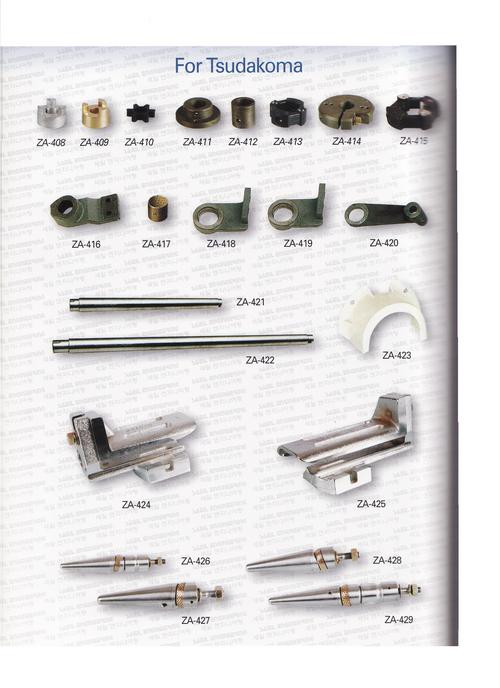

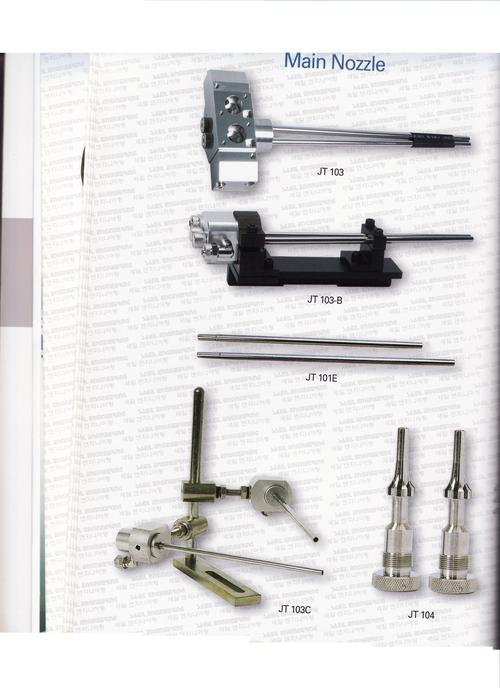

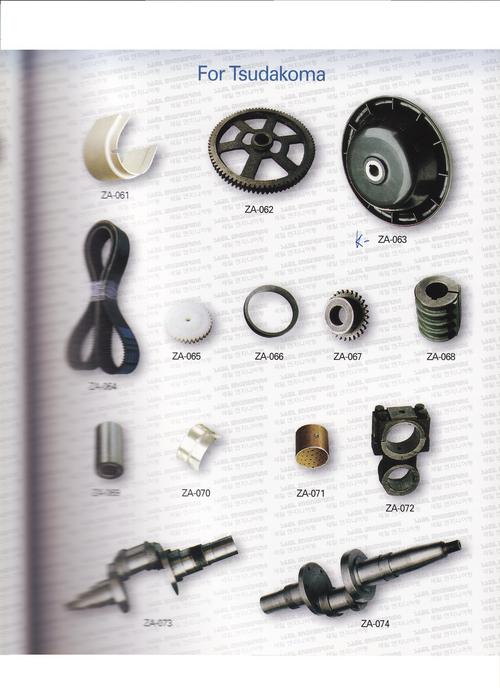

Industrial Tsudakoma Airjet Spares

Product Details:

- Capacity High Performance

- Features Corrosion Resistant, Durable, Wear Resistant

- Thread Type Metric / Custom

- Size Standard/Customized

- Diameter 10 mm / 12 mm / Custom

- Surface Finish Precision Machined

- Thermal Conductivity Excellent

- Click to View more

X

Industrial Tsudakoma Airjet Spares Product Specifications

- Industrial Textile Weaving

- High Performance

- Corrosion Resistant, Durable, Wear Resistant

- Airjet Spare Parts

- Metric / Custom

- Tsudakoma Airjet Loom

- 10 mm / 12 mm / Custom

- Alloy Steel & Aluminum

- Standard/Customized

- Excellent

- Precision Machined

- Airjet Loom Spare Part

- Automatic

- Varies with Model

- Nozzle, Reed Holder, Gear

- Up to 1200 RPM

- Low

Product Description

Sourced from reliable vendors, these Industrial Tsudakoma Airjet Spares are manufactured with due diligence by making use of excellent quality raw materials. The quality of our offered spares in excellent in each aspects like surface finish, construction, dimensions or used material. Most commonly used in textile, jute and fabric industries, these spares are also tested on different parameters of quality by our professionals' team. Apart from this, the offered Industrial Tsudakoma Airjet Spares are offered in different specifications at marginal rates to the clients.

Features:

-

Sturdy construction

-

Dimensionally accurate

-

Rust free nature

-

Sturdiness

Engineered for Maximum Compatibility and Longevity

Our spares are tailored to fit every Tsudakoma Airjet Loom model, making them a versatile and strategic choice for textile manufacturers. Utilizing anodized or electroplated surfaces along with alloy steel and aluminum constructs, these parts exhibit advanced resistance to wear and corrosion, ensuring prolonged operation and a low-maintenance experience in high-demand industrial settings.

Precision Machining for Optimal Performance

Each componentnozzle, reed holder, or gearis meticulously precision-machined and available in standard or custom dimensions, meeting the specific requirements of every textile operation. Low noise emission and exceptional thermal conductivity facilitate top-speed weaving (up to 1200 RPM), supporting uninterrupted processes and robust output.

FAQs of Industrial Tsudakoma Airjet Spares:

Q: How do I ensure compatibility of these spares with my Tsudakoma Airjet Loom?

A: All offered spares are engineered to fit all Tsudakoma Airjet Loom models. They can be specified by model type, and custom sizes or thread types are available to suit any unique machinery configuration.Q: What are the installation requirements for these airjet spare parts?

A: Installation is straightforward, requiring minimal technical expertise. Components are designed for easy replacement, allowing quick swaps of nozzles, reed holders, or gears, often without needing special tools.Q: When should these spares be replaced to maintain optimal machine performance?

A: It is recommended to replace parts after their service life of over two years, or sooner if you notice reduced performance or visible wear. Regular monitoring will ensure your looms continue to operate at peak efficiency.Q: Where are these spares typically used within the textile industry?

A: These spares are primarily utilized in industrial textile weaving settings, specifically as replacement parts in Tsudakoma Airjet Looms across various textile manufacturing facilities.Q: What is the process for ordering customized parts?

A: For custom dimensions, finishes, or thread types, simply provide your technical specifications at the time of purchase. Our team will facilitate manufacturing and supply of parts that precisely match your operational requirements.Q: How does the precision machining and finishing benefit my operation?

A: Precision machining ensures exact fitment and reliable functionality, while the anodized/electroplated finish enhances the spares durability. This minimizes downtime, reduces noise, and supports high-speed weaving without frequent replacements.Q: What are the main advantages of choosing these spares?

A: Key benefits include high corrosion and wear resistance, low maintenance needs, elevated thermal conductivity, high performance at speeds up to 1200 RPM, and compatibility with all Tsudakoma models. These attributes help extend the productivity and lifespan of your machinery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email