Loom Rapier Spare Parts

Product Details:

- Thread Type Metric

- Part Type Spare Part

- Surface Finish Polished

- Noise Level Low

- Diameter As per OEM Standard

- Features Corrosion Resistant, Precision Engineered

- Thermal Conductivity Moderate

- Click to View more

X

Loom Rapier Spare Parts Product Specifications

- Metric

- Rapier Loom Spare Part

- High Durability

- Multiple (As per Design)

- Customized

- Standard/Customized

- Above 800 MPa

- Moderate

- Alloy Steel

- Corrosion Resistant, Precision Engineered

- As per OEM Standard

- Low

- Polished

- Spare Part

- Rapier Loom

- Replacement Part

Product Description

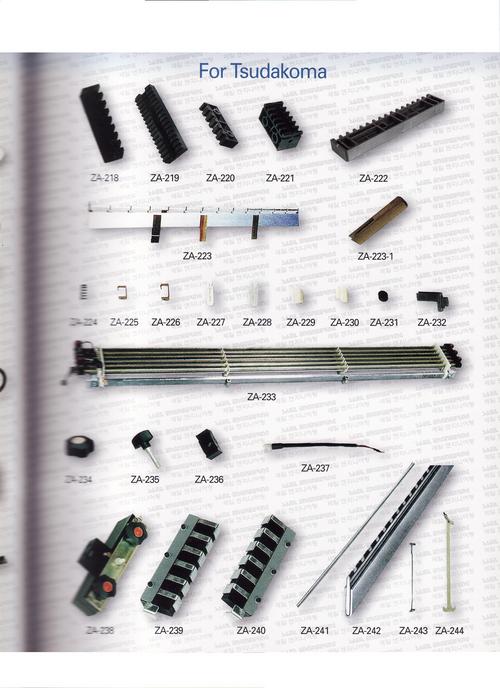

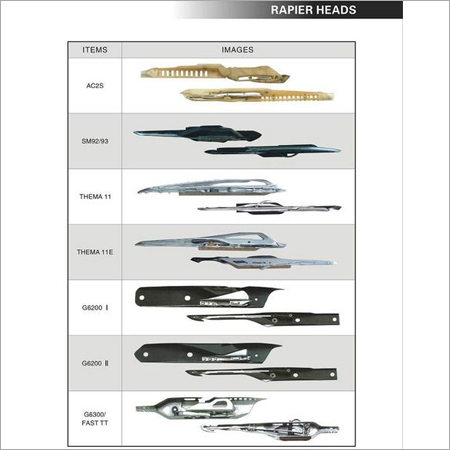

Fostered with a team of highly experienced professionals, we have been able to trade and supply Rapier Loom Spare Parts. These spare parts are extensively used in the textile and jute machines by utilizing shedding, picking and battening process. By following market defined standards, our trusted vendors manufacture these spare parts by making use of high quality raw material coupled with contemporary technology. Besides, these Loom Spare Parts are available in different shapes and sizes in order to fulfills the requirements of clients.

Features:

- Robust construction

- Durable finish standard

- Accurate dimensions

- Precisely engineered

Universal Compatibility and Customization

Designed for universal use across multiple rapier loom brands, our spare parts are available in both standard and fully customized sizes. This ensures seamless integration with diverse machinery, optimizing the functionality and efficiency of your textile production line.

Engineered for Strength and Precision

Every part is crafted from high-grade alloy steel, heat-treated for maximum durability and a tensile strength exceeding 800 MPa. With a tight 0.01 mm tolerance and polished finish, these components reduce wear, maintain silence in operation, and extend your machines service life.

Reliability from Origin to Application

Manufactured in India, these spare parts are packaged securely and engineered with corrosion-resistant finishes and multiple-hole designs. Their chemical resistance and moderate thermal conductivity offer safe, reliable operation in demanding textile environments.

FAQs of Loom Rapier Spare Parts:

Q: How do I ensure these rapier spare parts fit my loom model?

A: These spare parts are engineered for universal compatibility with multiple rapier loom brands. Simply provide your looms OEM specifications or request a customized dimension to guarantee an exact fit.Q: What makes alloy steel a preferred material for these parts?

A: Alloy steel imparts high tensile strength (over 800 MPa), durability, and corrosion resistance. This material selection ensures the replacement parts withstand the operational stresses of textile machinery and maintain reliable performance over extended service periods.Q: When should I consider replacing rapier loom components?

A: Replace rapier loom parts when you notice abnormal wear, increased noise, or diminished fabric quality. Early replacement prevents costly downtime and ensures continued high-capacity production.Q: Where are these loom spare parts manufactured and supplied from?

A: All components are produced in India following stringent quality control protocols and are available through established importers and suppliers nationwide.Q: What is the maintenance requirement for these replacement parts?

A: Our parts require minimal maintenance due to their precision engineering, corrosion resistance, and robust design. Routine cleaning and regular inspection are generally sufficient to ensure optimal performance.Q: How does the packaging ensure product safety during transport?

A: Each part is securely packed in either box or carton packaging, safeguarding against physical damage and contamination during shipment to your facility.Q: What are the key benefits of using your rapier loom spare parts?

A: Key benefits include high durability, precise fit, chemical resistance, long service life, and low operational noise. These features minimize downtime, extend machinery lifespan, and contribute to superior textile output.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email