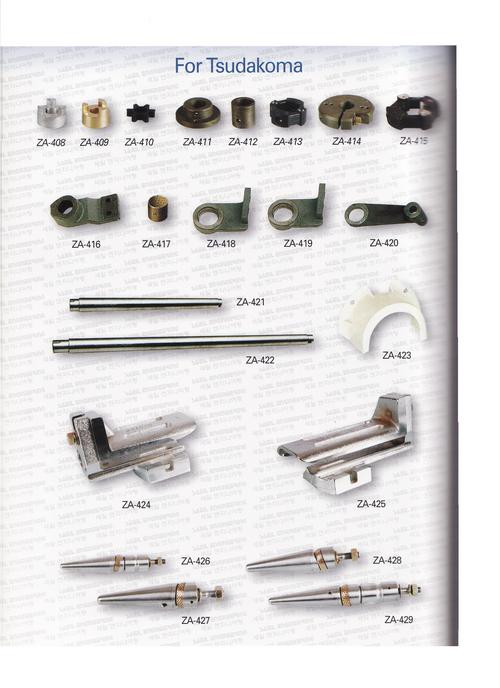

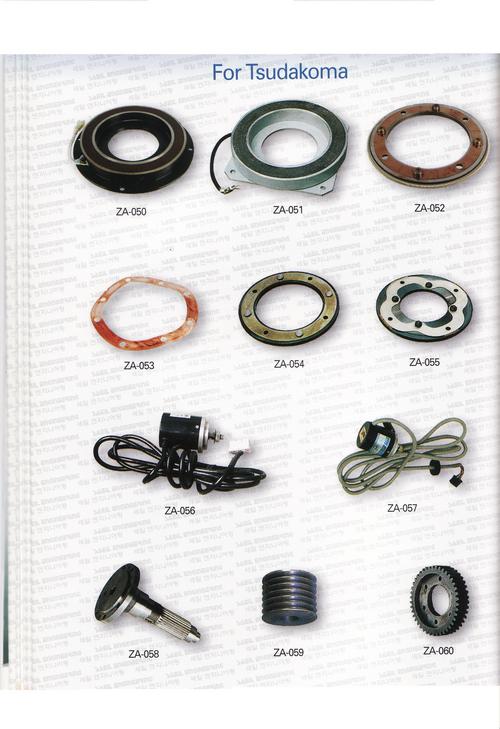

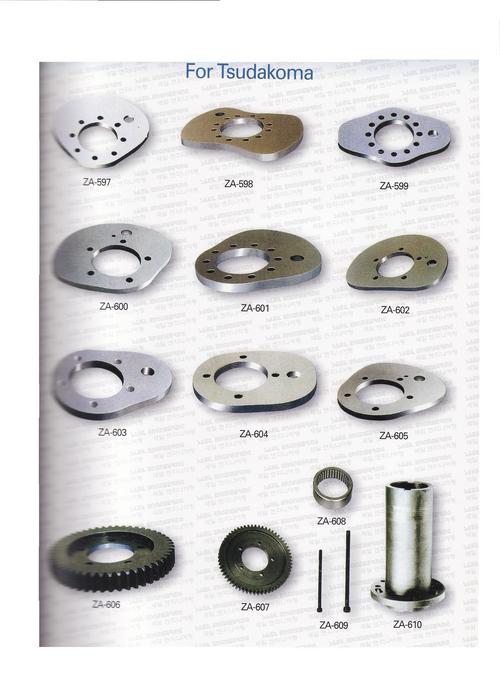

Tsudakoma Air Jet

500-3000 INR/Piece

Product Details:

- Automation Grade Automatic

- Tensile Strength 900 MPa

- Capacity High Air Flow

- Thermal Conductivity High

- Diameter Customizable

- Features Corrosion Resistant, Durable, Precise Jet Control

- Part Type Textile Machine Spare Part

- Click to View more

X

Tsudakoma Air Jet Price And Quantity

- 500-3000 INR/Piece

- 1 , , Piece

Tsudakoma Air Jet Product Specifications

- Textile Machine Spare Part

- Air Jet

- Corrosion Resistant, Durable, Precise Jet Control

- Customizable

- Up to 1200 m/min

- Nozzle

- 900 MPa

- Automatic

- Approx. 300 grams

- Weaving Machine

- High

- High Air Flow

- Smooth Polished

- Standard

- Direct Mount

- 60 HRC

- Low

- Standard / Custom

- For Weft Insertion in Looms

Tsudakoma Air Jet Trade Information

- KOLKATA

- Cash in Advance (CID), Cash Advance (CA)

- 100 , , Piece Per Month

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Nagaland, South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Haryana, North India, Punjab, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

Product Description

Presenting the Tsudakoma Air Jet Nozzlethe paragon of cost-effective industrial solutions for textile manufacturing. Designed for top-notch performance, this valiant component suits ZAX and ZW Series looms, delivering high-precision weft insertion up to a speed of 1200 m/min. Crafted from corrosion-resistant, smooth-polished silver, this durable spare part withstands temperatures up to 60C, featuring a hard, efficient design with thermal conductivity and a 5000-hour service life. Its high air flow, top accuracy, and direct mount ensure ephemeral downtime. Experience a superior, dependable upgrade for your weaving machineideal for Indias thriving textile sector.

Optimal Textile Plant Performance

The Tsudakoma Air Jet is meticulously engineered for use in industrial textile manufacturing, excelling in weaving plants seeking consistent efficiency. Its direction of use is straightforward: direct mounting to compatible weaving machines for high-precision weft insertion across both general and specific textile operations. With its customizable diameter and smooth surface, the nozzle guarantees seamless integration and superior jet control, making it indispensable for both routine and demanding production environments.

Expansive Export Markets & Rapid Dispatching

The Tsudakoma Air Jet is highly sought-after in leading global textile markets, with strong supply ability to meet large-scale orders for Indian importers and suppliers. Delivery timelines are streamlinedexpect swift dispatching and the option for express shipping upon request. The asking price remains competitive, reflecting the nozzles durable construction and automated precision. Every order is meticulously packed and shipped to ensure reliable arrival, supporting textile operations worldwide with unwavering efficiency.

Optimal Textile Plant Performance

The Tsudakoma Air Jet is meticulously engineered for use in industrial textile manufacturing, excelling in weaving plants seeking consistent efficiency. Its direction of use is straightforward: direct mounting to compatible weaving machines for high-precision weft insertion across both general and specific textile operations. With its customizable diameter and smooth surface, the nozzle guarantees seamless integration and superior jet control, making it indispensable for both routine and demanding production environments.

Expansive Export Markets & Rapid Dispatching

The Tsudakoma Air Jet is highly sought-after in leading global textile markets, with strong supply ability to meet large-scale orders for Indian importers and suppliers. Delivery timelines are streamlinedexpect swift dispatching and the option for express shipping upon request. The asking price remains competitive, reflecting the nozzles durable construction and automated precision. Every order is meticulously packed and shipped to ensure reliable arrival, supporting textile operations worldwide with unwavering efficiency.

FAQs of Tsudakoma Air Jet:

Q: How do I install the Tsudakoma Air Jet nozzle in my weaving machine?

A: Installation is direct and user-friendly. Simply mount the nozzle onto compatible ZAX or ZW Series weaving machines as per the provided guide. Its standard size and customizable diameter allow seamless integration with most looms.Q: What benefits does the Tsudakoma Air Jet provide for textile manufacturers?

A: This air jet offers high accuracy in weft insertion, increased speed up to 1200 m/min, long service life, and reliable performance in demanding industrial environments, all while maintaining low noise and energy efficiency.Q: When should I replace the Tsudakoma Air Jet nozzle?

A: The nozzle is designed for a service life of up to 5000 hours. Replacement is recommended at the end of this period, or if there is a noticeable decrease in performance or air flow efficiency.Q: Where can I use this air jet nozzle?

A: It is ideal for application in industrial textile manufacturing plants, specifically within weaving machines for weft insertion. It suits both specialized and general production lines requiring durable, precise spare parts.Q: What is the process for adjusting air flow on this nozzle?

A: The Tsudakoma Air Jet features accessible flow adjustment controls. Operators can fine-tune air flow settings to match fabric and process requirements, ensuring maximum efficiency and optimal weaving results.Q: How does the air jets corrosion resistance benefit textile operations?

A: Its corrosion-resistant silver construction extends the lifespan of the nozzle and maintains top performance, even in humid or high-wear environments, minimizing downtime and replacement costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email