Tsudakoma Air Jet Parts

Product Details:

- Thread Type Metric and Imperial threads (varies by part)

- Size Standard, customized sizes available as per Tsudakoma Air Jet Machine requirements

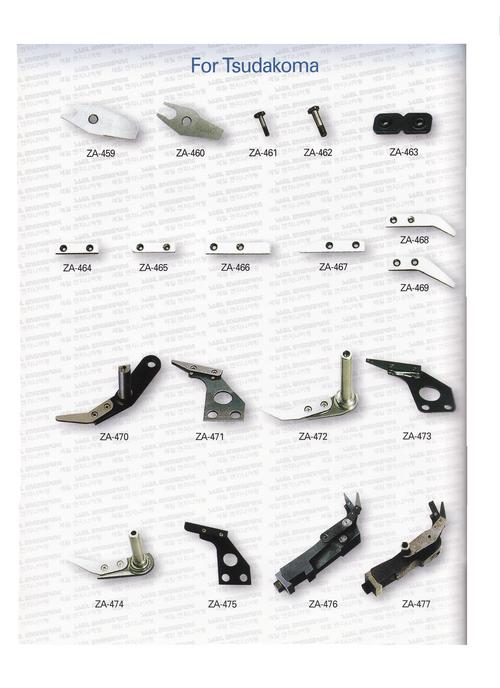

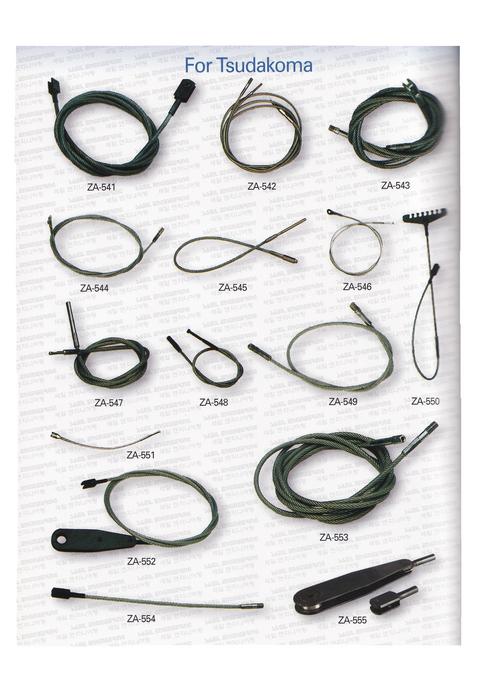

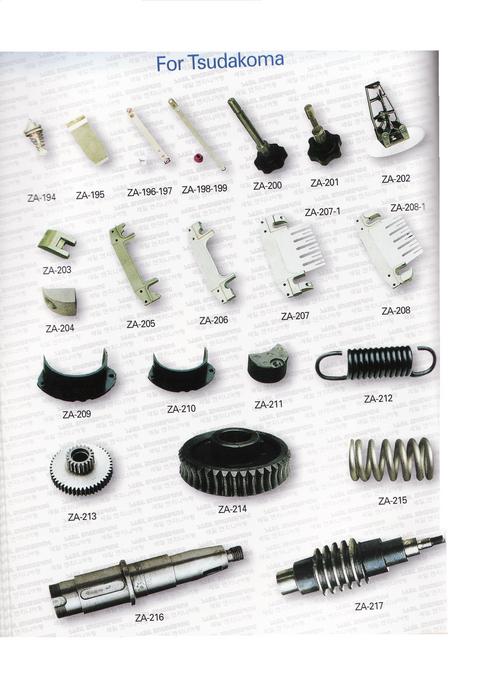

- Part Type Picker, Relay Solenoid, Nozzle, Valve, Housing, Harness, Clamp etc.

- Thermal Conductivity High thermal stability under loom conditions

- Product Type Weaving Loom Spare Part

- Textile Machine Type Tsudakoma Air Jet Loom

- Speed Efficient operation up to 1200 RPM

- Click to View more

X

Tsudakoma Air Jet Parts Product Specifications

- Varies by component; available on request

- High thermal stability under loom conditions

- Weaving Loom Spare Part

- Efficient operation up to 1200 RPM

- Picker, Relay Solenoid, Nozzle, Valve, Housing, Harness, Clamp etc.

- Tsudakoma Air Jet Loom

- Standard, customized sizes available as per Tsudakoma Air Jet Machine requirements

- Metric and Imperial threads (varies by part)

Product Description

With the utmost perfection, these Tsudakoma Air Jet Parts are manufactured with the use of excellent grade raw materials and the inculcation of pioneering techniques by our vendors. Highly acknowledged for their fine finish, easy installation and high durability, the offered parts are most commonly used as important accessory for their installation in airjets used in textile industry. Our quality controller keep checking the provided parts on various parameters in order to remove any possibility of defect. Moreover, clients can avail these Tsudakoma Air Jet Parts at reasonable rates from us.

Features:

-

Dimensional accuracy

-

Corrosion resistance

-

Easy to install

-

Rigid structure

Precision and Compatibility

Every Tsudakoma Air Jet Part is precisely machined to 0.01mm, guaranteeing a perfect fit and smooth function within Tsudakoma ZAX series looms. This outstanding accuracy, combined with compatibility across ZAX, ZAX9100, and ZAX9200 models, ensures seamless integration and improved textile production efficiency.

Durability and Thermal Stability

With an anodized metallic finish in silver or grey, these air jet parts boast resistance to abrasion and corrosion. Their high thermal stability supports continuous operation at temperatures up to 60C, making them reliable even under demanding weaving conditions common in high-speed textile manufacturing.

FAQs of Tsudakoma Air Jet Parts:

Q: How do I determine which Tsudakoma Air Jet Part is suitable for my specific loom model?

A: Identify your loom modelTsudakoma ZAX, ZAX9100, or ZAX9200and consult the components specifications for compatibility. Since parts are available in standard and custom sizes, you may also request dimensions tailored to your machines requirements for best results.Q: What benefits do the metallic anodized finish and high-precision machining provide?

A: The metallic anodized finish offers excellent durability against wear and corrosion, while the 0.01mm machining accuracy ensures optimal performance and longevity. These features together contribute to consistent operation and reduced maintenance downtime.Q: When should Tsudakoma Air Jet Parts be replaced or serviced?

A: It is recommended to inspect and replace parts during scheduled maintenance or when efficiency drops. Components like pickers, solenoids, or nozzles should be monitored regularly and swapped out at the first sign of wear to maintain peak loom speed and fabric quality.Q: Where can I source Tsudakoma Air Jet Parts in India?

A: These air jet parts are available through authorized importers and suppliers in India. You may contact your local supplier for industrial-standard packing, OEM services, and details on customized orders for Tsudakoma air jet loom components.Q: What is the process for ordering customized sizes and thread types?

A: To order custom sizes or threads (metric or imperial), provide the required dimensions and specifications based on your machines needs. The supplier will manufacture parts with precision engineering to match your Tsudakoma air jet loom and ensure optimal compatibility.Q: How easy is it to install or replace Tsudakoma Air Jet Parts?

A: These parts are designed for straightforward installation and replacement, following the looms standard protocols. With clear packaging and precise construction, maintenance can be performed efficiently by technicians with basic textile machinery knowledge.Q: What are the primary advantages of using Tsudakoma Air Jet Parts in textile looms?

A: Key advantages include enhanced speed up to 1200 RPM, high thermal stability under loom conditions, minimized downtime due to easy maintenance, and compatibility with multiple loom models, resulting in superior textile production quality and operational reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email