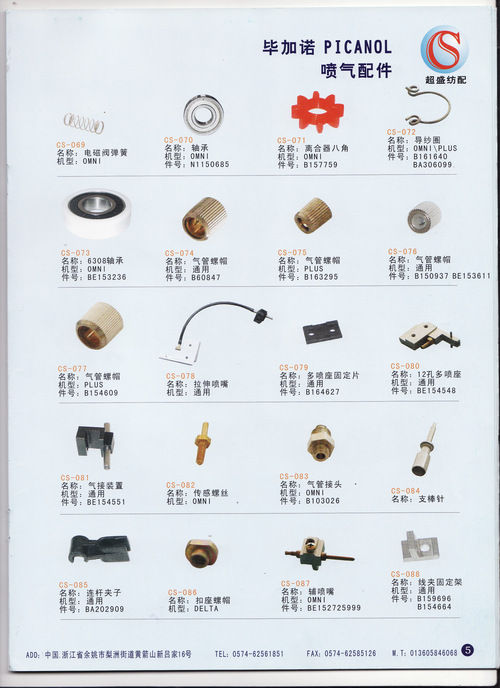

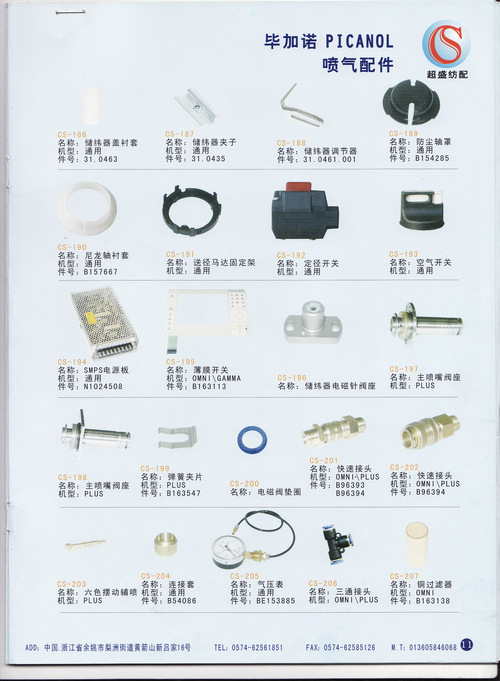

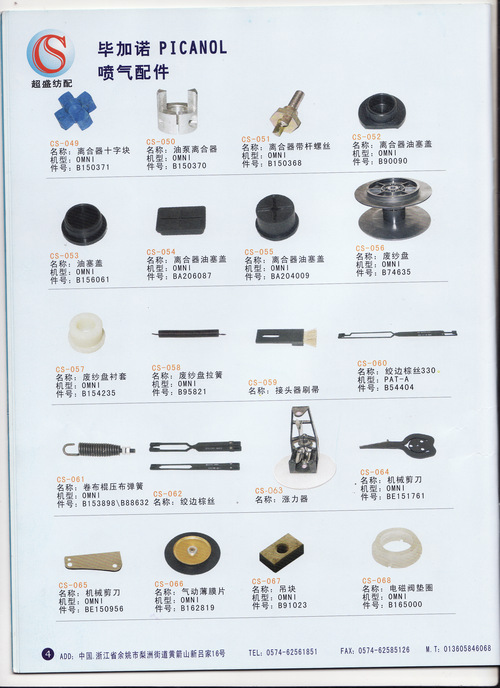

Picanol Air Jet Machine Parts

Product Details:

- Thread Type Metric

- Diameter Precise, as per OEM specification

- NO. Of Hole As per OEM specification

- Thermal Conductivity Standard for textile spares

- Noise Level Low

- Mounting Type Bolted / Fixed

- Surface Finish Anodized / Polished / Coated

- Click to View more

Picanol Air Jet Machine Parts Price And Quantity

Picanol Air Jet Machine Parts Product Specifications

- Bolted / Fixed

- Low

- Metric

- Precise, as per OEM specification

- Standard for textile spares

- As per OEM specification

- Air Jet Loom

- Alloy Steel / High Grade Aluminum

- Weaving Loom Spare Parts

- High Performance

- Air Jet Machine Parts

- Standard, Compatible with Picanol Air Jet Looms

- Operates at up to 1000 rpm

- Nozzle / Valve / Connector (as per model)

- Automatic

- Up to 600 MPa

- As per model

- Anodized / Polished / Coated

- Corrosion Resistant, Durable, Precise Fitting

Product Description

By the time of our establishment in 2004, we are known as a versatile organisation engaged in offering Picanol Air Jet Machine Parts. The offered airjet is manufactured with the utmost perfection using optimum quality components and the progressive methods under the visionary guidance of our reliable vendors. Used for weaving and related operations related to the textile industries, this air jet is widely applauded by our clients for its outstanding features. Besides, we offer this Picanol Air Jet Machine Parts in various specifications at marginal rates to the clients.

Features:

- Corrosion resistance

- Easy installation

- Application specific design

- Highly durable

Specifications

| Brand Name | Picanol Rapier |

| Usage | Textile Industry |

| Performance | Optimum |

| Resistivity | Corrosion & Chemical resistant |

| Range | Drive Wheel, Gamma, Picanol Gtm, Picanol Gtx |

| Installation | Easy to install |

Precision and Reliability for Textile Production

Picanol Air Jet Machine Parts provide accurate fit and high operational speed, up to 1000 rpm, supporting dependable textile manufacturing. Their bolted or fixed mounting offers stability, while metric threads facilitate easier installation. With each part adhering to stringent quality and compatibility standards, consistent performance on Picanol Air Jet Looms is ensured.

ISO Certified Quality and Advanced Features

Manufactured under ISO 9001:2015 certification, these spare components feature enhanced durability and corrosion resistance. Their anodized, polished, or coated surfaces increase longevity, reducing maintenance and downtime. Designed with OEM precision, they support high tensile loads and maintain thermal conductivity suited for demanding textile operations.

FAQs of Picanol Air Jet Machine Parts:

Q: How do I determine if these parts are compatible with my specific Picanol Air Jet Loom model?

A: Compatibility is ensured for Picanol Omniplus, Delta, and other Air Jet Loom models. To confirm, match your looms model number with our product listing or consult the OEM specifications provided for each part type.Q: What process do you follow to ensure the quality of each Air Jet Machine part?

A: Each part is manufactured according to ISO 9001:2015 standards, using alloy steel or high-grade aluminum. Rigorous inspections are conducted to verify precise fitting, dimensional accuracy, and surface finish before packaging.Q: When should I consider replacing my Air Jet Loom parts?

A: Replacement is recommended during scheduled maintenance or if signs of wear and reduced performance appear. Using OEM-spec spare parts helps maintain high machine speed and reliability.Q: Where are these Picanol Air Jet Machine Parts primarily supplied from?

A: We are a leading importer and supplier based in India, distributing genuine spare and component parts for textile machines nationwide.Q: What are the benefits of using parts with OEM-specified diameter and number of holes?

A: Components with OEM-specified diameter and hole configuration guarantee precise fitting, optimal airflow, and efficient functioning, reducing mechanical stress and operational noise.Q: How does the anodized or coated surface finish impact machine performance?

A: Anodized or coated surfaces enhance corrosion resistance and durability, minimizing maintenance frequency and supporting stable, high-speed textile production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+