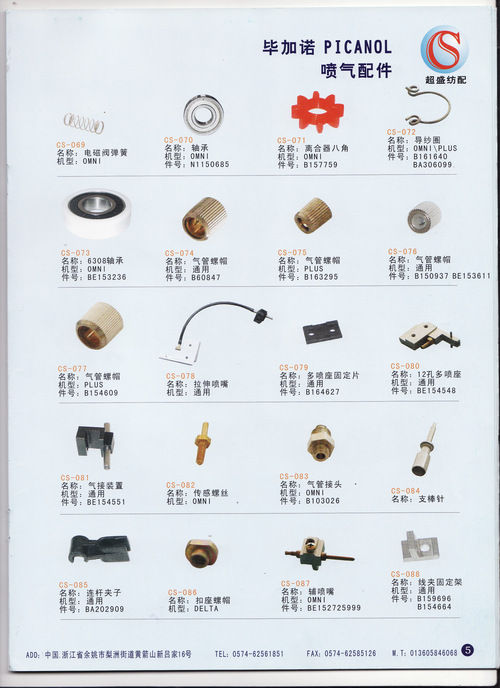

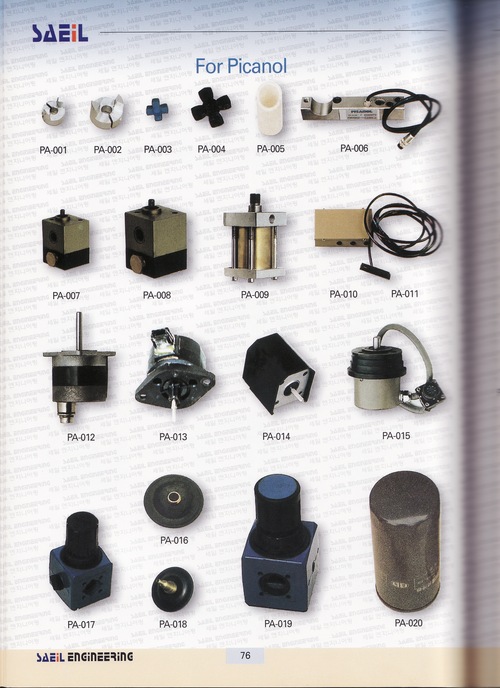

Picanol Airjet Loom Machinery Parts

Product Details:

- Diameter Up to 60 mm

- Surface Finish Polished

- Thread Type Metric

- Size Customized as per requirement

- Noise Level Low

- Thermal Conductivity Good heat dissipation

- Tensile Strength Above 1000 MPa

- Click to View more

X

Picanol Airjet Loom Machinery Parts Price And Quantity

Picanol Airjet Loom Machinery Parts Product Specifications

- Above 1000 MPa

- High wear resistance

- Automatic

- Precision engineered, corrosion resistant, sturdy design

- Spare Part

- As per model specification

- Loom Machinery Part

- Airjet Loom Spare

- As per specification

- Picanol Airjet Loom

- Varies by component

- Up to 60 mm

- Polished

- Metric

- Textile weaving machinery

- Low

- Customized as per requirement

- Alloy Steel

- Good heat dissipation

Product Description

We have marked a distinct position in this domain by providing an excellent grade Picanol Airjet Loom Machinery Parts. These parts are manufactured by deft team of professionals using supreme quality basic materials with the aid of innovative techniques. Having defect free nature, the offered parts are suitable for manufacturing as well as repairing of air jet loom machines. These Picanol Airjet Loom Machinery Parts are highly recognized for their accurate dimension and durable clamping loops.

Key points:

- Sturdiness

- Robust design

- Longer life

- Excellent mechanical strength

Specifications

| Brand Name | Picanol Rapier |

| Usage | Textile Industry |

| Performance | Optimum |

| Resistivity | Corrosion & Chemical resistant |

| Range | Drive Wheel, Gamma, Picanol Gtm, Picanol Gtx |

| Installation | Easy to install |

Precision Engineered for Optimal Performance

Each Airjet Loom spare part is meticulously designed using CNC machining processes. This ensures superior accuracy, tight tolerances, and consistent quality. As a result, our parts reliably increase operational stability while extending the lifespan of your textile weaving equipment.

Exceptional Material Strength and Durability

Manufactured from robust alloy steel, these spare parts possess a tensile strength exceeding 1000 MPa and feature a polished, corrosion-resistant surface. Their sturdy construction and high wear resistance make them ideal for demanding textile environments, contributing to reduced downtime.

Tailored Compatibility and Support

Our components are suitable for every Picanol Airjet Loom model and can be customized in size, threading, or number of holes based on individual machine specifications. With OEM service and export-standard packaging, we support both small-scale operations and large-scale importers in India.

FAQs of Picanol Airjet Loom Machinery Parts:

Q: How are Picanol Airjet Loom Machinery Parts customized to fit different loom models?

A: Our spare parts are designed with flexibility in mind, supporting all Picanol Airjet Loom models. We offer customized dimensions, thread types, and the number of holes according to your looms specifications, ensuring precise alignment and smooth installation.Q: What is the manufacturing process for these spare parts?

A: Each part is produced using advanced CNC machining, allowing for high-precision engineering, superior finish, and tight adherence to specified measurements. This method ensures consistent quality and superior performance in demanding textile weaving conditions.Q: When should I consider replacing my airjet loom spare parts?

A: Replacement is typically needed when you notice decreased efficiency, increased noise, or visible wear on current components. Regular maintenance and timely replacement help maintain operational reliability and prevent unexpected loom downtime.Q: Where can I order these parts, and are they available throughout India?

A: You can procure our Picanol Airjet Loom spare parts from authorized importers and suppliers across India. We guarantee safe export-standard packaging for secure transport to any region in the country.Q: What are the primary advantages of using CNC-machined, corrosion-resistant alloy steel parts for textile weaving?

A: CNC-machined alloy steel parts offer robust durability, high tensile strength above 1000 MPa, and excellent corrosion resistance. This translates to lower maintenance needs, reduced replacements, and consistent high-performance even under strenuous fabric production conditions.Q: How does the design of these machinery parts improve loom operation and safety?

A: Our precision-engineered parts decrease operational noise, ensure sturdy integration, and feature good thermal conductivity for optimal heat dissipation. This enhances both the safety of the loom and the quality of woven textiles.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email