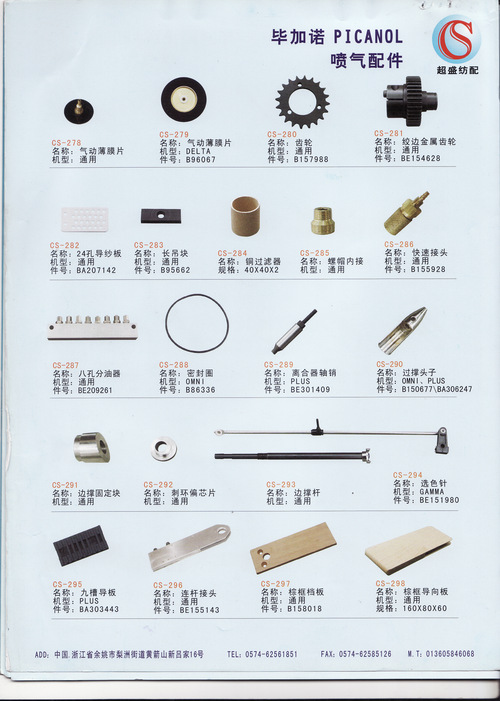

Picanol Airjet Loom Spares

Product Details:

- Tensile Strength Above 600 MPa

- NO. Of Hole As per design

- Surface Finish Polished / Coated

- Automation Grade Automatic

- Diameter Standard / As per model

- Part Type Loom Spare Part

- Noise Level Low

- Click to View more

X

Picanol Airjet Loom Spares Price And Quantity

Picanol Airjet Loom Spares Product Specifications

- Standard / As per model

- Loom Spare Part

- Precision Engineered, Durable, Corrosion Resistant

- Low

- Standard

- As per specification

- Standard / As per requirement

- Metric / As applicable

- High Performance

- Spare Part

- For Picanol Airjet Loom Machinery

- Above 600 MPa

- Lightweight / As per item

- Metal Alloy / Engineering Plastic

- As per design

- Picanol Airjet Loom

- Polished / Coated

- Automatic

- Airjet Loom Spare Parts

Product Description

Specifications

| Brand Name | Picanol Rapier |

| Usage | Textile Industry |

| Performance | Optimum |

| Resistivity | Corrosion & Chemical resistant |

| Range | Drive Wheel, Gamma, Picanol Gtm, Picanol Gtx |

| Installation | Easy to install |

Precision Spares for Peak Loom Performance

Every Picanol Airjet Loom Spare part is engineered for accuracy and reliability. Using premium metal alloys or engineering plastics, these spares meet or exceed textile machinery standards, ensuring seamless integration and consistent output. Suitable for both standard and custom specifications, they provide textile manufacturers a dependable choice for high-volume, automated weaving operations.

Superior Durability and Corrosion Resistance

The corrosion-resistant finish protects each part from moisture and harsh textile environments, ensuring longevity. Precision engineered to withstand high tensile stress and wear, these spares support extended machine uptime and reduce the risk of unexpected breakdowns, delivering excellent value to textile businesses across India.

Versatile Compatibility and Easy Installation

Designed for compatibility across all models of Picanol Airjet Looms, these spare parts come in standard or model-specific dimensions. With metric thread types and customized options per requirement, the installation process is straightforward, minimizing loom downtime, and enabling efficient maintenance or upgrades.

FAQs of Picanol Airjet Loom Spares:

Q: How do I determine the right size and specification for a Picanol Airjet Loom Spare?

A: To select the correct spare part, refer to your looms model and technical documentation for size and dimension specifications, or consult the supplier directly. Custom sizes and threading are available to match your exact needs.Q: What benefits do these spare parts offer for textile operations?

A: These spares are precision engineered for high durability, corrosion resistance, and low noise, ensuring reliable loom operation. Their high tensile strength and tailored fit lead to longer part lifespans and reduced machinery downtime.Q: When is it recommended to replace loom spares on Picanol Airjet machines?

A: Spare parts should be replaced at the first sign of wear, corrosion, or decreased loom performance. Regular maintenance schedules based on machine usage are advised for optimal productivity and to prevent unexpected breakdowns.Q: Where can I purchase Picanol Airjet Loom Spares in India?

A: These spare parts are available through authorized importers and suppliers across India, who can provide them in box or carton packaging according to your order, even for a minimum quantity of one piece.Q: What is the process for installing these loom spare parts?

A: Installation typically involves removing the old part and fitting the new spare according to the looms manual. Compatibility with all Picanol Airjet Loom models and standard metric threads ensures straightforward replacement, supported by the supplier if needed.Q: How are these spare parts designed to handle the demands of the textile industry?

A: Constructed from resilient metal alloys or engineering plastics, and boasting a tensile strength above 600 MPa, these spares are built for high performance, precision, and endurance in demanding textile production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email