Picanol Omni Air Jet

Product Details:

- Tensile Strength Superior (meets OEM requirements)

- Hardness High (as per industrial standards)

- Automation Grade Automatic

- Part Type Complete Loom Machine

- Noise Level Low (<85 dB)

- Size Standard (customizable)

- Capacity Up to 1200 picks/min

- Click to View more

Picanol Omni Air Jet Price And Quantity

Picanol Omni Air Jet Product Specifications

- Automatic

- Complete Loom Machine

- 2200 kg

- High (as per industrial standards)

- Superior (meets OEM requirements)

- Commercial Textile Weaving

- Standard (customizable)

- Weaving Machine

- Main Unit

- Up to 1200 picks/min

- Optimized for textile applications

- 4420 mm x 1800 mm x 1600 mm

- Air Jet Loom

- Low (<85 dB)

- Up to 1200 RPM

Product Description

Among our exclusive gamut of textile machines, we have put forward a huge array of Picanol Omni Air Jet. At our vendors' premises, this airjet is manufactured with the use of excellent quality components and the pioneering technology by experienced professionals. Our offered airjet has wide ranging applications in various textile industries. Known for its precise dimensions, premium finish and robust construction, the provided airjet is also tested on various parameters by our quality experts. Besides, we provide this Picanol Omni Air Jet at marginal rates to the clients.

Features:

- Sturdy construction

- Application specific structure

- Rust proof nature

- Dimensional accuracy

Specifications

| Brand Name | Picanol Rapier |

| Usage | Textile Industry |

| Performance | Optimum |

| Resistivity | Corrosion & Chemical resistant |

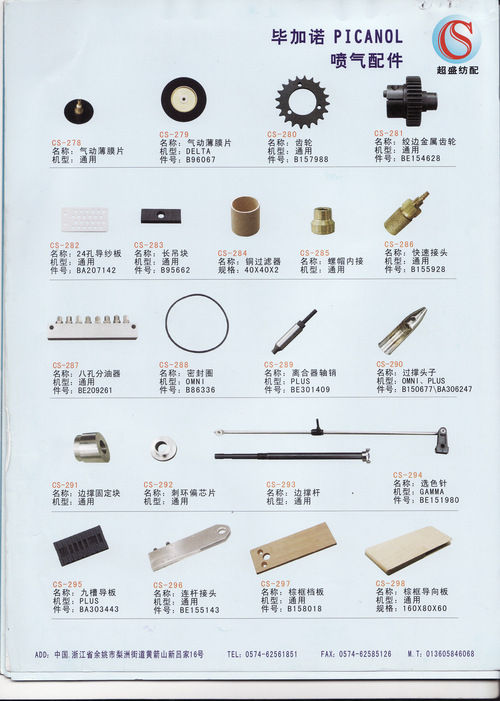

| Range | Drive Wheel, Gamma, Picanol Gtm, Picanol Gtx |

| Installation | Easy to install |

Advanced Weft Insertion Technology

The electronic controlled air jet system propels weft yarns efficiently, enhancing weaving speed and accuracy. This technology minimizes yarn breakage and optimizes fabric quality across various material types including cotton, synthetics, and blends. With speeds reaching up to 1200 picks per minute, manufacturers can achieve high output while maintaining fabric integrity.

Smart Control & Automation

Equipped with a microprocessor-based digital control system and an intuitive touchscreen panel, the Picanol Omni Air Jet offers precise settings and real-time monitoring. The centralized automated lubrication system maintains consistent performance, reducing maintenance intervals and extending machine life. The compatibility with Dobby, Cam, and Jacquard shedding motions allows versatile fabric design possibilities.

Industrial-Grade Performance

Engineered for reliability, the loom features high hardness and superior tensile strength that meet OEM requirements and ensure longevity. With an optimized dimension (4420 mm x 1800 mm x 1600 mm) and a robust build weighing 2200 kg, it delivers stable, low-noise operation (<85 dB) ideally suited for commercial textile weaving environments in India.

FAQs of Picanol Omni Air Jet:

Q: How does the electronic controlled air jet system improve weaving efficiency?

A: The advanced air jet system uses electronic controls to precisely insert the weft yarn, enabling faster weaving speeds up to 1200 picks per minute. This reduces yarn breakage and enhances fabric uniformity, optimizing productivity for commercial weaving applications.Q: What types of fabrics can be produced with the Picanol Omni Air Jet weaving machine?

A: This machine is suitable for weaving cotton, synthetic, and blended yarn fabrics. Its robust configuration and compatible shedding motions allow users to manufacture diverse textile products, ranging from apparel to technical fabrics.Q: When should the lubrication system be serviced or checked?

A: The centralized automated lubrication system significantly reduces manual maintenance needs. However, periodic checks based on the manufacturers guidelines or operating hours are recommended to ensure optimal performance and prevent component wear.Q: Where is the Picanol Omni Air Jet loom typically installed?

A: It is primarily installed in commercial textile weaving plants in India, where high-speed, automatic looms are essential for large-scale production. Its customizable standard size allows integration into various factory layouts.Q: What is the process for changing cloth width on this machine?

A: Cloth width adjustments are model-dependent and involve changing the reed and associated settings through the touchscreen interface. Technicians should refer to detailed operation manuals for specific steps to ensure correct configuration for widths between 190 cm and 360 cm.Q: How does the touchscreen display interface benefit operators?

A: The touchscreen panel provides an intuitive control environment, allowing operators to monitor machine status, adjust parameters, and troubleshoot issues swiftly. This minimizes training time and maximizes operational efficiency.Q: What are the primary benefits of using this automatic weaving machine in commercial textile production?

A: Key benefits include high-speed operation, low noise levels, consistent fabric quality, reduced maintenance due to automated systems, and compatibility with various yarn types. These features collectively enhance productivity and reliability in industrial textile manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+