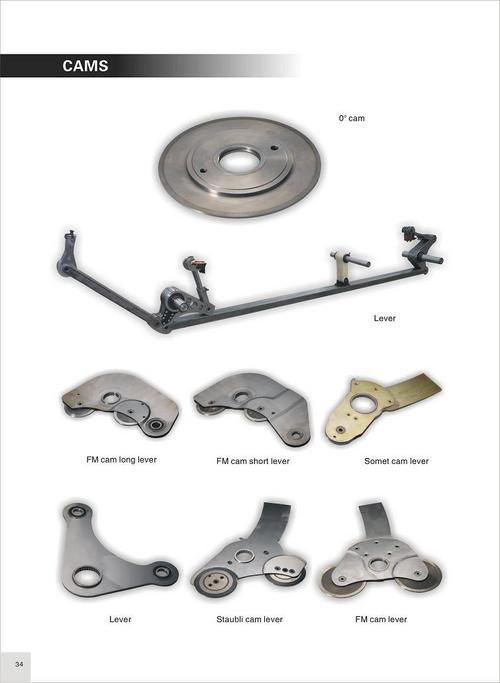

Sulzer Cams

Product Details:

- Tensile Strength >850 MPa

- Thermal Conductivity Good

- Size Standard/Customized

- NO. Of Hole As per Model

- Diameter Accurate As Per Drawing

- Part Type Weaving Loom Spare

- Features High Performance, Wear Resistant, Precision Engineered

- Click to View more

X

Sulzer Cams Product Specifications

- Standard/Customized

- Vary As per Size

- As per Model

- Sulzer Loom

- For Weaving Machine

- >850 MPa

- Suitable up to 900 RPM

- Standard

- Good

- Heavy Duty

- Black Oxide/Polished

- Cam

- Alloy Steel

- Sulzer Cam

- Accurate As Per Drawing

- Weaving Loom Spare

- High Performance, Wear Resistant, Precision Engineered

- Low

Product Description

Counted amidst a noteworthy organization, we are engaged in providing optimum grade Sulzer Cams. By deft professionals, these cams are manufactured using quality assured basic materials at our highly advanced unit. To protect from corrosion, the offered cameras are tested under different parameters. These Sulzer Cams are available in customized sizes and design and finishes to fulfill the need of clients.

Key features:

- Robust construction

- Longer life

- Suitable for weaving and sulzer loom machines

- Smooth surface finish and easy to install

Unmatched Precision and Engineering

Sulzer Cams are meticulously crafted to deliver a high-precision finish, aligning perfectly with OEM standards. Their engineering ensures an accurate diameter as per the provided technical drawing, making them reliable for demanding weaving operations. Each cam is wear resistant and designed with high tensile strength above 850 MPa, guaranteeing longevity even at high speeds.

Customizable Solutions for Every Need

We offer Sulzer Cams in both standard and customized sizes, tailored to accommodate diverse weaving machine models. Whether you require specific hole counts or special dimensions, our OEM service provides solutions that meet your exact requirements. Every cam is manufactured to deliver seamless compatibility and superior performance.

Durable Materials for Reliable Performance

Manufactured from premium alloy steel, these cams feature surface finishes like black oxide or polishing to enhance longevity and corrosion resistance. Their heavy-duty capacity and good thermal conductivity assure dependable performance, even under rigorous industrial operation conditions.

FAQs of Sulzer Cams:

Q: How do Sulzer Cams enhance weaving machine performance?

A: Sulzer Cams are precision-engineered from high-grade alloy steel and finished for optimal wear and corrosion resistance, ensuring smooth and reliable operation at speeds up to 900 RPM. This improves the overall efficiency and lifespan of weaving machines.Q: What is the process for ordering customized Sulzer Cams?

A: To order customized Sulzer Cams, you can share your technical drawings or specifications such as size, diameter, and number of holes. Our OEM service will tailor-make the cams to fit your unique Sulzer loom requirements, ensuring high compatibility and precision.Q: Where can these cams be used, and what models are they compatible with?

A: These cams are compatible with all Sulzer loom models and are specially designed as weaving loom spare parts. They are ideal for any textile manufacturing unit utilizing Sulzer weaving machines, ensuring a proper fit and high performance.Q: What benefits do the surface finishes provide?

A: The black oxide and polished surface finishes enhance corrosion resistance and reduce wear, extending the cams service life. They also ensure the cams maintain a smooth operation and sustain the heavy-duty conditions of textile workshops.Q: How does the packaging ensure product safety during transport?

A: Each Sulzer Cam is packaged in an export-quality box to guard against physical damage and corrosion during transit, ensuring the part arrives in optimal condition for installation.Q: When should Sulzer Cams be replaced?

A: Sulzer Cams should be replaced during routine loom maintenance or when signs of wear, noise increases, or diminished weaving performance are observed. Regular replacement helps uphold the machines efficiency and reduces unexpected downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email