Sulzer Projectile Looms Spare Parts

Product Details:

- Tensile Strength Up to 900 MPa

- Capacity High Load Bearing

- Noise Level Low

- Thread Type Metric / Custom

- Diameter As per Part Specification

- NO. Of Hole As per OEM Specification

- Surface Finish Polished / Corrosion Resistant

- Click to View more

Sulzer Projectile Looms Spare Parts Price And Quantity

Sulzer Projectile Looms Spare Parts Product Specifications

- Projectile Loom Spare Part

- Precision Engineered, Durable, Wear Resistant, Easy Installation

- Standard

- Industrial Textile Weaving

- Varies by Part

- Standard and Customized Sizes

- Sulzer Projectile Loom

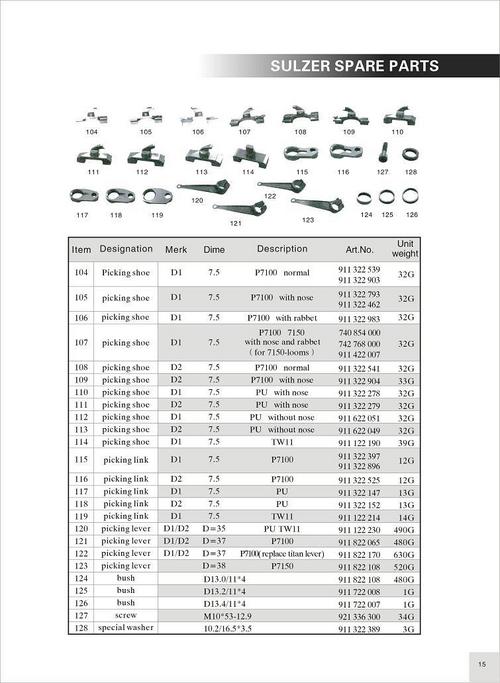

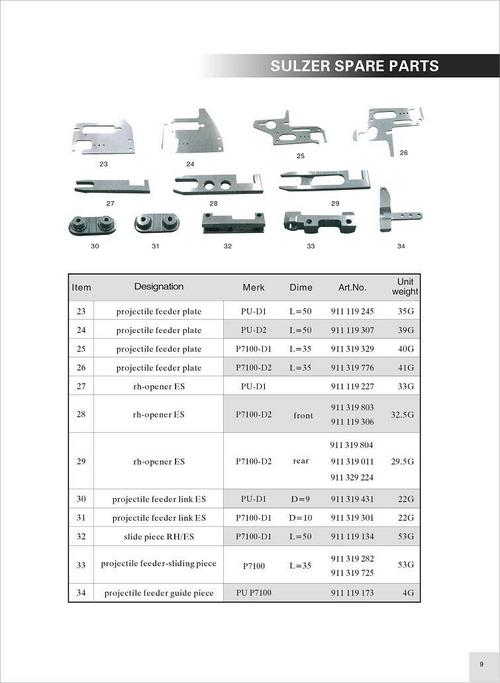

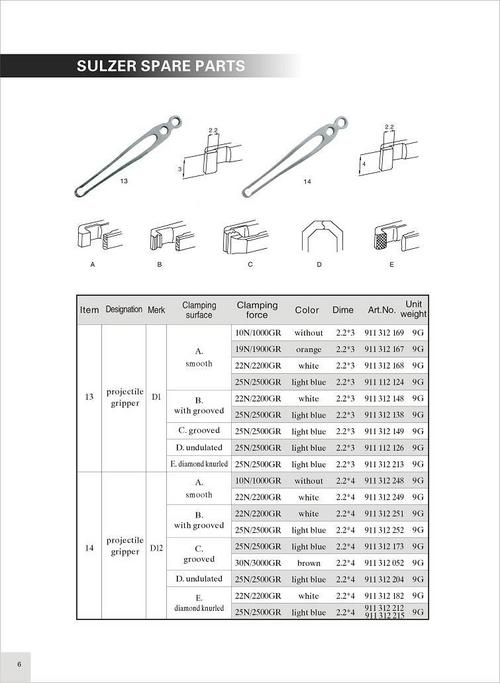

- Projectile, Gripper, Picking Shoe, Drive Shaft, etc.

- Polished / Corrosion Resistant

- As per Part Specification

- As per OEM Specification

- Metric / Custom

- Low

- High Load Bearing

- As per model specification

- Up to 900 MPa

- Loom Spare Parts

Product Description

Being a reputed name due to our versatile business approach, we are affianced to supply an exclusive assortment of Sulzer Projectile Looms Spare Parts. Spares offered by us are manufactured with the use of excellent quality raw materials and the pioneering techniques at our vendors' end. Highly applauded by the clients owing to their robust construction and superior surface finish, these parts are also tested on various parameters of quality. Moreover, clients can avail these Sulzer Projectile Looms Spare Parts at marginal rates from us.

Features:

- High strength

- Accurate dimensions

- Corrosion resistance

- Easy installation

Specification

| Brand Name | Sulzer Rapier |

| Use | Used In Textile Or Garment Machines For Manufacturing Loom, Fabric And Yarn |

| Usage | Textile Industry |

| Material | Metal |

| Installation | Easy |

| Resistivity | Corrosion & Chemical resistant |

Engineered for Compatibility & Performance

Every spare part is meticulously crafted for seamless integration with Sulzer PU, P7100, P7200, TW11, TW12, and other Sulzer looms. The use of CNC machining and heat treatment ensures consistent quality, precise fit, and efficient operation in textile weaving applications. Enhanced corrosion resistance and wear resistance result in reduced maintenance and downtime.

Comprehensive Customization & Sizing

Standard and customized sizes as well as surface finishes, including polished and corrosion-resistant options, are available to meet diverse operational needs. Thread types can be supplied in metric or custom specifications. Each parts dimensions, weight, and diameter align with the model or OEM requirements, ensuring optimal performance.

Dependable Quality & Packaging

Adhering to ISO 9001:2015 certification, these parts undergo stringent quality checks. Packaging options, including export-standard boxes or pallets, safeguard the products during transport. Bulk orders start from 10 pieces, making them accessible for both small-scale importers and large textile manufacturers across India.

FAQs of Sulzer Projectile Looms Spare Parts:

Q: How are Sulzer Projectile Looms Spare Parts ensured to be compatible with multiple models?

A: These spare parts are specifically engineered to match Sulzer PU, P7100, P7200, TW11, TW12, and other Sulzer models, adhering to precise OEM specifications for size, diameter, and hole configuration, ensuring seamless compatibility and easy installation.Q: What benefits do the corrosion-resistant and heat-treated features provide?

A: Corrosion resistance extends the service life of each part, while heat treatment increases their strength and durability, reducing the frequency of replacements and ensuring high performance in industrial weaving environments.Q: When should I consider customizing the size or thread type of a spare part?

A: Customization is recommended if your loom setup requires specific dimensions, thread types, or you need to match legacy equipment. Custom orders ensure you receive spare parts tailored to unique machinery needs and operational preferences.Q: Where are these spare parts manufactured and how are they packaged for delivery?

A: The spare parts are produced using advanced CNC machining and are packaged in export-standard boxes or pallets to ensure safe transit. The packaging meets international shipping standards, safeguarding components during import to India or other destinations.Q: What is the process for ordering Sulzer Projectile Looms Spare Parts?

A: Orders can be placed for a minimum of 10 pieces in either standard or custom variants. The parts are manufactured to ISO 9001:2015 quality standards, and OEM/ODM services are available for special requirements. Bulk or custom orders can be coordinated with the supplier directly.Q: How do these spare parts contribute to improved textile machine performance?

A: Engineered for high load-bearing, low noise, and precision fit, these spare parts ensure stable loom operation, reduce wear on associated components, and enhance the overall quality and efficiency of textile production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+