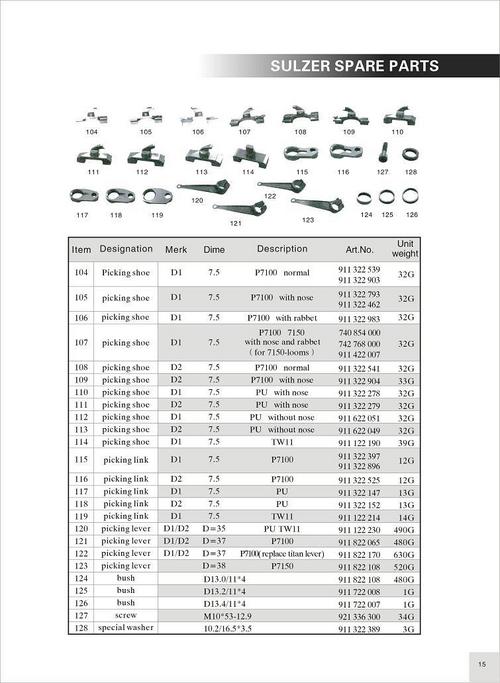

Sulzer Loom Spare Parts

Product Details:

- Thermal Conductivity Good, suitable for continuous use

- Noise Level Low

- Features Durability, Precision Machining, Easy Installation, Rust Proof

- Size Standard, Customizable

- Diameter Varies by part (6mm40mm typical)

- Part Type Spare/Replacement

- Thread Type Metric/Imperial as required

- Click to View more

X

Sulzer Loom Spare Parts Product Specifications

- Varies by part (0.510 kg)

- Sulzer Loom

- Metric/Imperial as required

- Up to 800 MPa

- Sulzer Loom Spare Parts

- Supports up to 700 rpm

- Varies by part (6mm40mm typical)

- Spare/Replacement

- Standard, Customizable

- Customized

- Durability, Precision Machining, Easy Installation, Rust Proof

- Loom Gears, Shafts, Cams, Bearings, etc.

- Good, suitable for continuous use

- Low

Product Description

With an aim to provide immense satisfaction to clients, we are engaged in offering superior grade Sulzer Loom Spare Parts. At our modern unit, These parts are manufactured under the strict guidance of diligent professionals with the aids of advanced techniques. The provided parts are suitable for textile and garments industrial applications owing to their lightweight and easy handling. These Sulzer Loom Spare Parts are ideal for repairing loom as well as weaving machines to provide smooth fluency during working.

Features:

- Dimensional accuracy

- High durability

- Precise design

- Compactness

Exceptional Durability and Precision

Every Sulzer Loom spare part is crafted using high-grade materials and advanced machining technology. These parts withstand continuous operation, wear, and high impact, while offering 0.01 mm dimensional accuracy, ensuring minimal downtime and consistent textile production. Their rust-proof, corrosion-resistant finish extends service life and enhances reliability for textile manufacturers.

Seamless Compatibility and Flexible Customization

Tailored to fit a range of Sulzer projectile and rapier looms, our spare parts can be customized by size (diameter 6mm40mm, weight 0.510 kg) and thread type (metric or imperial) to suit specific requirements. This ensures excellent integration with various loom configurations, enabling optimal machine performance and longevity.

Secure Packaging and Simple Installation

Each component arrives securely boxed, minimizing risk during transport and handling. The design supports quick, straightforward installation, allowing for fast replacements and maintenance, so your textile operations remain uninterrupted. Our boxed and labeled packaging increases convenience for bulk import or supply in India.

FAQs of Sulzer Loom Spare Parts:

Q: How do Sulzer Loom Spare Parts support continuous, high-speed weaving operations?

A: Sulzer Loom Spare Parts are designed to handle speeds up to 700 rpm and provide extended service life. Their wear-resistant, precision-machined construction enables them to endure continuous use, minimizing operational interruptions for textile manufacturers.Q: What types of Sulzer loom models are these spare parts compatible with?

A: These parts are engineered to fit both Sulzer projectile and rapier looms. With customizable dimensions and thread types, they integrate easily with various models and configurations, supporting a wide range of textile machinery in the industry.Q: When should I consider replacing my Sulzer Loom spare parts?

A: Replacement cycles depend on usage and loom workload, but typically, parts should be inspected and replaced annually to maintain efficiency and prevent unforeseen breakdowns. Regular maintenance ensures optimal loom performance and longevity.Q: Where are Sulzer Loom Spare Parts packaged and supplied?

A: Spare parts are securely boxed, labeled, and supplied by Indian importers and suppliers. This packaging ensures safe transport, reduces damage risk, and simplifies inventory handling for large-scale textile operations.Q: What is the process for ordering customized Sulzer Loom Spare Parts?

A: To order custom parts, select your preferred size, thread type, and component type. Minimum order quantities start at 10 pieces, with options for metric or imperial threads, specific weights, and diameters to fit your loom needs.Q: How do the corrosion-resistant and rust-proof features benefit textile operations?

A: Corrosion and rust resistance ensure that parts maintain their integrity in humid or variable environments, reducing frequent replacements and machine downtime, and supporting consistent, high-quality textile production.Q: What advantages do these spare parts offer in terms of installation and maintenance?

A: Precision machining and boxed packaging make these parts easy to install, requiring minimal technical expertise. Their durability and extended service life reduce maintenance frequency, saving time and operational costs for textile manufacturers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email