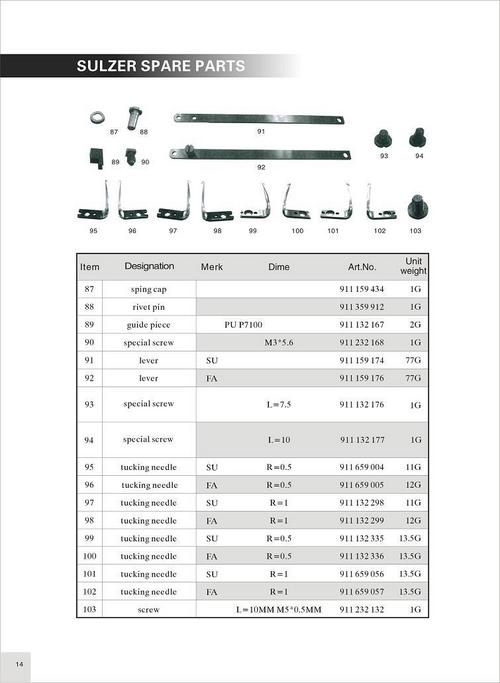

Sulzer Spring Cap

Product Details:

- NO. Of Hole 1

- Size Standard

- Automation Grade Manual

- Mounting Type Press Fit

- Diameter Approx. 32 mm

- Surface Finish Polished

- Part Type Spare Part

- Click to View more

X

Sulzer Spring Cap Price And Quantity

Sulzer Spring Cap Product Specifications

- Spare Part

- Corrosion Resistant, Durable, Compact Design

- Approx. 20 g

- High

- Polished

- Spring Cap

- Approx. 32 mm

- Spring Cap

- Sulzer Weaving Machine

- Press Fit

- Textile Looms

- Manual

- 1

- Stainless Steel

- Standard

Product Description

Since 2004, our quality concerned enterprise has been engrossed in bringing forth top grade Sulzer Spring Cap. This cap is manufactured by deft team of dedicated professionals using quality checked raw materials at highly advanced unit. The offered cap is highly cherished among clients due to its rust proof nature and flawless finish. This Sulzer Spring Cap is available in different specifications to suit the require off our valued patrons.

Key points:

- Rugged design

- Robustness

- Defect free nature

- Long life

Superior Quality and Durability

Crafted from high-grade stainless steel, the Sulzer Spring Cap is designed for longevity and consistent performance in demanding textile manufacturing environments. The corrosion-resistant polished finish ensures the cap remains sturdy and visually appealing, even with continuous use. Its robust build supports high tensile strength, enhancing overall loom reliability.

Precision Fit for Sulzer Looms

Tailored for Sulzer PU, TW11, and Projectile looms, the spring caps standard circular design and press fit mounting method enable straightforward installation and reliable operation. The precise placement of the cap helps maintain proper spring alignment, reducing wear and tear and supporting seamless textile production.

Optimized for Textile Applications

Engineered for use in Sulzer weaving machines operating up to 120C, this spring cap is ideal for the rigorous conditions found in textile factories. Its single-hole, compact construction fits perfectly within loom assemblies. Each piece is supplied in secure packagingeither box or polybagfor safe handling, delivery, and storage.

FAQs of Sulzer Spring Cap:

Q: How is the Sulzer Spring Cap installed on a weaving loom?

A: The Sulzer Spring Cap is designed for press fit mounting. Simply align the cap with the designated slot or recess on the loom and apply pressure to securely fit it into place, ensuring proper spring placement without the need for additional tools.Q: What is the benefit of using a stainless steel spring cap in Sulzer looms?

A: Using stainless steel ensures the spring cap offers excellent durability, corrosion resistance, and high tensile strength. This means it can withstand frequent use in demanding textile environments, maintaining performance and extending the service life of your loom parts.Q: When should the Sulzer Spring Cap be replaced?

A: Replacement is recommended during regular loom maintenance or if signs of excessive wear, deformation, or corrosion appear. Consistent use within the products long service life and appropriate conditions should minimize the frequency of replacements needed.Q: Where can I use the Sulzer Spring Cap?

A: This spring cap is specifically compatible with Sulzer PU, TW11, and Projectile weaving machines. It is suitable for use in various textile factories where these loom models are employed, ensuring secure and accurate spring placement.Q: What packaging options are available for the Sulzer Spring Cap?

A: The Sulzer Spring Cap is available in both box and polybag packaging options. This ensures safe handling, transportation, and convenient storage for bulk orders or individual components.Q: How does the design of the Sulzer Spring Cap enhance loom performance?

A: Its compact, circular design with a single hole ensures precise spring alignment while the smooth, polished surface minimizes friction and wear. This contributes to smoother machine operation and reduces the likelihood of mechanical failures during textile production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email