Tsudakoma Airjet Loom Spares

Product Details:

- Tensile Strength Up to 900 MPa

- Thread Type Metric

- Noise Level Low

- Automation Grade Automatic

- Diameter Varies (According to machine spec)

- Part Type Nozzle, Clamp, Guide, Holder

- Thermal Conductivity Excellent

- Click to View more

X

Tsudakoma Airjet Loom Spares Price And Quantity

- INR

Tsudakoma Airjet Loom Spares Product Specifications

- Airjet Loom Spare Part

- Metric

- Up to 900 MPa

- Weft Insertion and Fabric Formation

- Low

- Automatic

- Varies (According to machine spec)

- Nozzle, Clamp, Guide, Holder

- Designed for operation up to 1200 RPM

- Excellent

- Tsudakoma Airjet Loom

- Custom sizes available as per model requirement

- Standard and custom dimensions

- Configurable as per loom part

- Precision Polished

- Lightweight (depends on part type)

Product Description

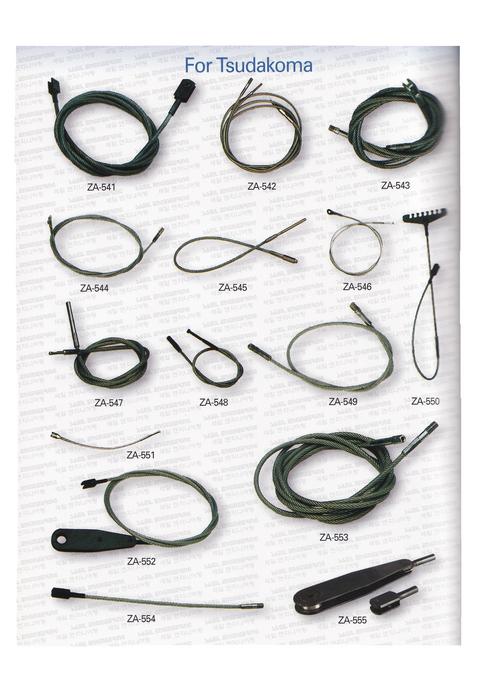

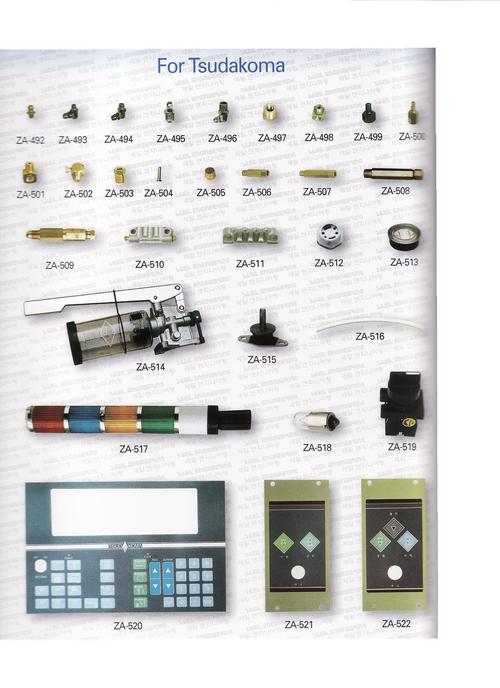

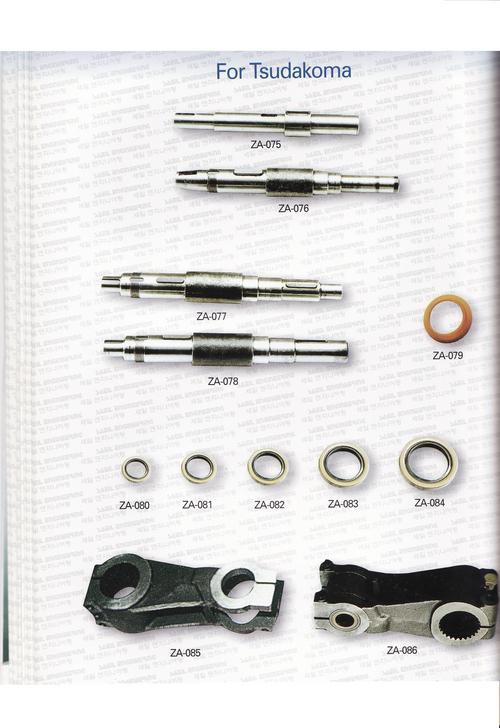

For many years, we are affianced in offering a supreme quality assortment of Tsudakoma Airjet Loom Spares. Sourced from reliable vendors of the market, the offered parts are manufactured by making utilization of quality tested raw materials and the progressive techniques in accordance with the set industry standards. As per the requirements of the clients, the provided spares are available in various sizes, finishes and other specifications. Moreover, we offer these Tsudakoma Airjet Loom Spares at highly competitive rates to the clients.

Features:

-

Easy installation

-

Rust resistance

-

Sturdy design

-

Precise dimensions

Engineered for Humid Environments

Our loom spares boast an advanced corrosion-resistant alloy, making them particularly well-suited for textile factories facing high humidity levels. With precision-polished surfaces, these parts maintain performance and appearance, reducing the risk of rust or degradation over time.

Custom Fit for Every Airjet Loom

We offer spares in a variety of sizes and configurations, tailored to the requirements of different Tsudakoma Airjet Loom models. From nozzles and clamps to guides and holders, every piece is meticulously manufactured to ensure a seamless fit and maintain operational efficiency.

Longevity and Performance Combined

Each component is produced to deliver an extended service life, withstanding high temperatures and intense working cycles at up to 1200 RPM. Excellent tensile strength and thermal conductivity ensure ongoing reliability and low maintenance throughout their use in industrial settings.

FAQs of Tsudakoma Airjet Loom Spares:

Q: How are these loom spares designed to withstand humid environments?

A: These spares are manufactured using corrosion-resistant materials and finished with precision polishing, enabling them to resist rust and deterioration commonly caused by humidity. Their robust construction ensures superior longevity even in moisture-prone conditions.Q: What kind of installation process should I expect for these spares?

A: Installation is designed to be quick and straightforward, with custom sizes and precise tolerances ensuring each part fits seamlessly into your Tsudakoma Airjet Loom, minimizing downtime during maintenance or replacement.Q: When should I replace my Tsudakoma Airjet Loom spares?

A: While these spares have an extended service cycle and require minimal maintenance, it is recommended to monitor for any signs of wear during regular loom inspections. Replacement schedules may vary depending on operational intensity, but extended durability means fewer replacements are needed.Q: Where are these spare parts manufactured and how are they packaged?

A: All spares are made in India and undergo strict quality control. Each component is safely packed in secure export-grade packaging to prevent damage during transit, ensuring they reach you in excellent condition.Q: What process ensures the quality and precision of each spare part?

A: A stringent manufacturing process involving exact machining, metric threading, and surface polishing guarantees every part meets high precision and tolerance standards. This assures seamless installation and optimal loom performance.Q: Can I get custom-sized parts for different loom models?

A: Yes, custom sizes and configurations are available based on specific Tsudakoma Airjet Loom requirements. Provide your models specifications, and tailored sparesincluding nozzle hole configurations and dimensionswill be supplied.Q: What benefits do these spares offer for industrial textile applications?

A: Their corrosion resistance, high tensile strength (up to 900 MPa), superior thermal conductivity, and low noise emission contribute to reliable high-speed weaving, reduced operational interruptions, and overall enhanced productivity in textile manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email