Projectile Looms Parts

Product Details:

- Features High Wear Resistance, Corrosion Resistant, Accurate Fitment

- Size Standard / As per requirement

- Noise Level Low

- Thermal Conductivity Standard

- Tensile Strength High (as per OEM specification)

- Thread Type Metric / Customized

- Surface Finish Polished / Nickel Plated / Zinc Coated

- Click to View more

X

Projectile Looms Parts Price And Quantity

Projectile Looms Parts Product Specifications

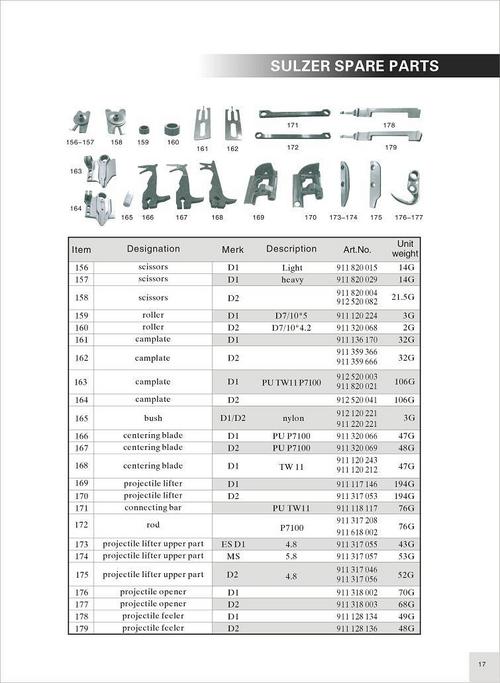

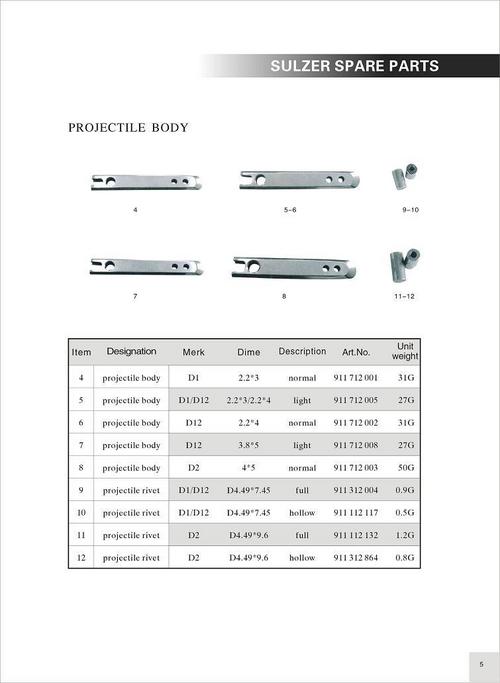

- Projectile Gripper, Projectile Feeder, Clamping Segment, etc.

- High Wear Resistance, Corrosion Resistant, Accurate Fitment

- Standard / As per requirement

- Standard / On Request

- Low

- Standard

- Projectile Looms Parts

- High (as per OEM specification)

- Projectile Loom

- Metric / Customized

- Polished / Nickel Plated / Zinc Coated

- 0.20 kg to 3 kg (varies per part)

- Alloy Steel / Hardened Steel / Stainless Steel

- As per OEM design

- Spare Part / Component

- Up to 1400 RPM

- Textile Weaving

- Heavy Duty

Product Description

A veteran team of quality aids us to offer a wide array of quality Projectile Looms Parts. By our vendors, these parts are precisely manufactured by making consistent improvisation of cutting-edge techniques and quality tested raw materials. Widely used in textile and jute industries for their installation in sulzer machines, the provided parts are very much acknowledged for their excellent durability and premium finish. Besides, we offer these Projectile Looms Parts Sulzer in different specifications at most economic rates to the clients.

Features:

- Precise dimensions

- Rust proof

- High strength

- Easy to install

Robust Material & Precision Engineering

Crafted from alloy steel, hardened steel, or stainless steel, every part undergoes precision machining for guaranteed dimensional accuracy. A specialized induction hardening process ensures superior wear resistance and longevity, making these components ideally suited for demanding industrial textile environments.

Comprehensive Compatibility & OEM Support

These spare parts are engineered to fit seamlessly with leading projectile looms like Sulzer, Somet, and more. Whether you need standard dimensions or custom sizes, OEM solutions are available to meet specific requirements. Each part is thoroughly inspected for accurate fitment and durability.

Optimized Packaging & Fast Supply

Designed for robustness and safe transit, our components are packed in corrugated boxes or bubble wrap. With a supply ability of up to 1,000 pieces per month, timely delivery is assured for bulk or urgent industrial needs across India.

FAQs of Projectile Looms Parts:

Q: How do I determine if these parts are suitable for my projectile loom?

A: Our projectile loom parts are designed for compatibility with major brands such as Sulzer and Somet, and can fit other leading machines as well. Simply provide the loom model or OEM specifications, and well confirm the correct part and ensure accurate fitment.Q: What is the manufacturing process for your loom spare parts?

A: All components are precision machined from high-strength metals, then undergo induction hardening for enhanced wear resistance. Surface finishes include polished, nickel plated, or zinc coated to provide corrosion protection and a smooth, reliable operation.Q: When should I consider replacing my projectile loom components?

A: Consider replacement when you notice increased noise, reduced loom efficiency, or visible signs of wear. Our parts maintain performance at high speeds (up to 1400 RPM) and under heavy-duty use, but timely replacement maximizes operational longevity.Q: Where can I source these projectile loom parts in India?

A: We are a distinguished importer and supplier based in India, delivering to textile mills and machinery service providers nationwide. Components are shipped securely in protective packaging to ensure they arrive in optimal condition.Q: What benefits do your loom parts offer for textile weaving applications?

A: These parts deliver high tensile strength, precise tolerance (Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email