Color Selectors

Product Details:

- NO. Of Hole Multiple (as per spindle count)

- Surface Finish Smooth matte finish

- Tensile Strength Above 30 MPa

- Automation Grade Automatic

- Thermal Conductivity Low

- Capacity Up to 12 colors selection

- Mounting Type Panel mounted

- Click to View more

X

Color Selectors Product Specifications

- Above 30 MPa

- Selector Module

- Yarn Dyeing, Textile Looms, Knitting Machines

- Color Selector

- Up to 120 selections/min

- Approximately 350 grams

- 65-80 Shore D

- Smooth matte finish

- Multiple (as per spindle count)

- 180 mm x 90 mm x 65 mm

- Panel mounted

- Varies by model

- Low Noise Operation

- Up to 12 colors selection

- Color selection in textile machinery

- Low

- Automatic

- Standard and custom sizes available

- User-friendly, Durable, High Accuracy, LED based

- Electronic Control Device

- ABS Plastic body with high-grade electronic components

- LED/LCD options

- <50 ms

- 20% - 90% RH (non-condensing)

- Max. 500 mA

- -20°C to 60°C

- Digital/Manual

- 0°C to 55°C

- 24V DC

- IP20

- Ideal for textile, yarn and weaving industries

Product Description

We are engaged in offering a wide range of Color Selectors that are known for their excellent dimensional stability. These selectors are procured from reliable vendors of the market and is manufactured using quality assured raw materials with the aid of contemporary techniques. The provided selectors are complete electronic solution for airjet weaving looms & rapier weaving looms. Finding usage in textile applications, these Color Selectors are highly cherished in the market.

Key points:

- Uniform thickness

- Available in different dimensions and thickness

- Excellent durability

- Shock proof

|

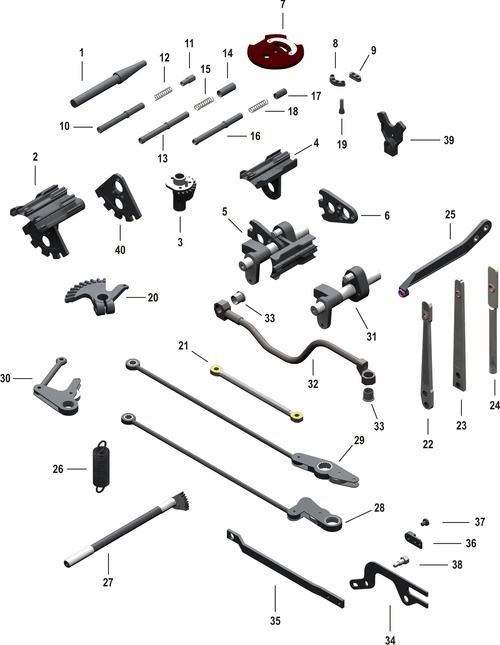

ID: |

TK No: | ART No: | Designation: |

| 1 | TK501 | 911141346 | Selector axle |

| 2 | TK502 | 911841071 | Selector Complete D1 L:90 |

| 2 | TK503 | Selector Complete D1 L:79 | |

| 3 | TK504 | 912141912 | Toothed segment D1 Z:11 |

| 3 | TK505 | 911741001 | Toothed segment D1 Z:7 |

| 4 | TK506 | Selector 2 colors | |

| 5 | TK529 | 911840144 | Selector 2 colors complete |

| 6 | TK545 | Plate for 2 colors selector | |

| 7 | TK507 | 912541261 | Locking Plate D1 |

| 8 | TK508 | 911241120 | Eyelet segment D1 |

| 9 | TK509 | 911340132 | Eyelet segment D1 2 colors |

| 10 | TK510 | 911341257 | Thread Tube D1 5/7,1/10,8x103,4 |

| 11 | TK511 | 911341136 | Pressure piece D1 |

| 12 | TK512 | 911141627 | Pressure spring |

| 13 | TK534 | Thread Tube D2 9/10/12x100 | |

| 14 | TK533 | Pressure piece L:32 | |

| 15 | TK535 | Pressure spring D12 | |

| 16 | TK537 | Thread Tube D2 9/10/12x98,60 | |

| 17 | TK536 | Pressure piece L:21,10 | |

| 18 | TK538 | Pressure spring D2 | |

| 19 | TK513 | 911241341 | Special screw |

| 20 | TK514 | 911141366 | Toothed Lever |

| 20 | TK515 | 911341064 | Toothed Lever |

| 21 | TK516 | 912541134 | Traction Rod |

| 22 | TK517 | 911814173 | Weft Tensioning lever |

| 23 | TK518 | 930814001 | Weft Tensioning lever |

| 24 | TK541 | 912514281 | Weft Tensioning lever |

| 25 | TK542 | 917750064 | Weft Tensioning Support L:194 |

| 25 | TK543 | 917750355 | Weft Tensioning Support L:213 |

| 26 | TK519 | 911114748 | Spring |

| 26 | TK520 | 911314502 | Spring |

| 27 | TK521 | 911141129 | Cam Driving shaft Z:6 |

| 27 | TK522 | Cam Driving shaft Z:7 | |

| 28 | TK523 | 912514203 | Roller lever |

| 29 | TK524 | 912514204 | Roller lever |

| 30 | TK525 | 912514105 | Roller lever |

| 31 | TK526 | 911840119 | Selector Shaft |

| 32 | TK527 | 911814154 | Control Bar |

| 33 | TK546 | 911314987 | BUSH |

| 34 | TK528 | 740939000 | Bend Bar |

| 35 | TK530 | 911840131 | Rod |

| 36 | TK531 | 911840141 | Stop piece |

| 37 | TK532 | 716392000 | Arresting Bolt |

| 38 | TK539 | 911340616 | Eccentric screw |

| 39 | TK547 | 715781000 | Stop disc |

| 40 | TK544 | Toothed plate for selector VSD |

Efficient Color Selection for Textile Machinery

This Color Selector is engineered for high-speed and accurate color choices in textile and yarn-related machines, making it an indispensable module for dyeing, weaving, and knitting processes. Its rapid selection speed and versatility in handling up to 12 distinct colors streamline production, enhancing output and reducing downtime.

Robust Construction and Reliable Performance

Made from ABS plastic and top-tier electronic components, the selector exhibits excellent hardness, tensile strength, and thermal stability. Its smooth matte finish and panel-mounted design facilitate integration, while its IP20 protection ensures safe operation in controlled industrial settings.

Customizable and User-Friendly Design

Available in standard and tailored sizes, the devices intuitive controlsdigital or manualcater to diverse operational needs. Clearly visible LED/LCD indicators, low-noise operation, and flexible mounting options make it suitable for a wide range of textile machinery configurations.

FAQs of Color Selectors:

Q: How does the Color Selector operate within textile machines?

A: The Color Selector uses a digital or manual control interface to manage up to 12 different color selections for textile machinery, such as yarn dyeing and knitting machines. Its electronic module enables quick, reliable switching with a response time of less than 50 milliseconds.Q: What benefits do LED or LCD indicators provide during color selection?

A: LED or LCD indicators offer clear, immediate feedback on selected colors and operating status, helping operators monitor performance and ensuring the accuracy of the selection process in fast-paced textile environments.Q: When and where is installation of the Color Selector recommended?

A: Installation is recommended during machinery setup or upgrades in environments such as textile factories, especially on yarn dyeing or weaving machines. The selector is designed for panel mounting and performs optimally in operating temperatures between 0C and 55C, with non-condensing humidity levels of 20% to 90% RH.Q: What is the typical installation process for the Color Selector?

A: The selector is panel-mounted using designated holes that match spindle counts. Standard installation involves securing the unit in the specified location, connecting the 24V DC power supply, and integrating it with existing machine controls, either digitally or manually as required.Q: How can the device be used to enhance textile production efficiency?

A: By enabling rapid and accurate color selectionup to 120 selections per minutethe Color Selector reduces manual errors, enhances automation, and supports high-volume output, benefitting textile manufacturers through improved speed and consistent dyeing or weaving results.Q: What are the key features that ensure durability and reliability of the Color Selector?

A: Constructed with a robust ABS plastic body, high-grade electronic components, and a smooth matte surface, the Color Selector offers high hardness, tensile strength, low thermal conductivity, and IP20 protection, leading to a long lifespan and sustained performance in challenging textile environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email