Projectile Lifter

Product Details:

- Noise Level Low

- Thermal Conductivity Moderate (optimized for textile machine environment)

- Hardness 58-62 HRC

- Features Durable, wear-resistant, easy installation, precision engineered

- Capacity Designed for robust projectile lifting

- Size Standard (Customized on request)

- Part Type Loom Spare Part

- Click to View more

X

Projectile Lifter Price And Quantity

- INR

- Silver / Natural Metal Finish

- Yes

- Extended (Up to 250,000 cycles)

- High

- Suitable for Sulzer Projectile Loom Models

- CNC Machined and Heat Treated

- Minimal

Projectile Lifter Product Specifications

- Projectile Lifter / Loom Spare

- 58-62 HRC

- Projectile Loom

- 1

- Textile Weaving Machine

- Alloy Steel

- 11 mm (custom sizes available)

- Moderate (optimized for textile machine environment)

- Bolt-On / Screw Mount

- Metric Fine Thread

- Low

- Up to 1200 picks/minute

- Standard (Customized on request)

- Loom Spare Part

- High Tensile (per textile machinery specification)

- 78 mm x 16 mm x 11 mm

- Designed for robust projectile lifting

- Precision Ground, Corrosion Resistant Coating

- Durable, wear-resistant, easy installation, precision engineered

- Automatic

- Projectile Lifter

- 0.28 kg

- Silver / Natural Metal Finish

- Yes

- Extended (Up to 250,000 cycles)

- High

- Suitable for Sulzer Projectile Loom Models

- CNC Machined and Heat Treated

- Minimal

Product Description

Having in-depth market experience, we are offering a quality tested the range of Projectile Lifter. At vendors advanced premises, this lifter is manufactured using the best grade raw materials with the aid of progressive machines under the guidance of experienced professionals. Find its application in textile industry, the provided lift is widely used for sulzer projectile loom. In addition to this, the offered Projectile Lifter can be bought from us at rock bottom prices by our prestigious clients.

Key points:

- Smooth edges

- Long life

- Anti-corrosive surface

- Known for sturdiness

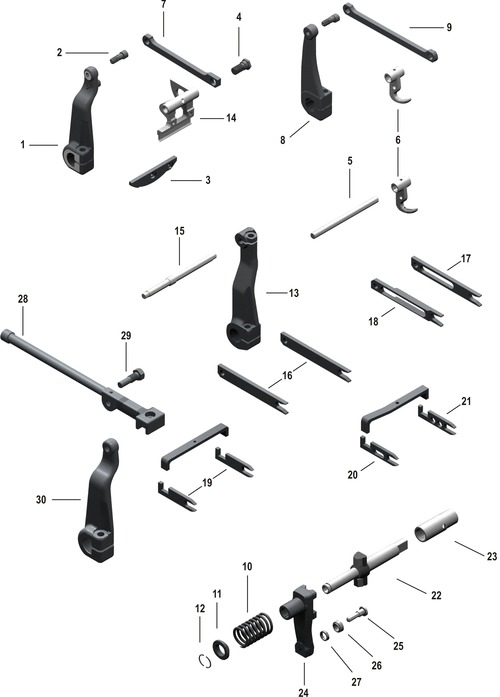

| ID: | TK No: | ART No: | Designation: |

| 1 | TK401 | 912517012 | Lever |

| 2 | TK402 | 911118124 | Eccentric axle |

| 3 | TK403 | 911317057 | Upper part of proj.lifter MS D1 |

| 3 | TK404 | 911317055 | Upper part of proj.lifter D1 ES |

| 3 | TK405 | 911317056 | Upper part of proj.lifter D2 |

| 3 | TK406 | 911117166 | Upper part of proj.lifter |

| 3 | TK407 | 911117137 | Upper part of proj.lifter MS D1 |

| 3 | TK408 | 911117102 | Upper part of proj.lifter ES D1 |

| 3 | TK456 | 911317046 | Up. part of proj.lifter ES D2 hard fiber |

| 4 | TK409 | 912500002 | Axle screw D9 L:29 |

| 4 | TK410 | 911817004 | Axle screw D11 L:29 |

| 4 | TK411 | 911118118 | Axle bolt D9 L:41 |

| 5 | TK412 | 911117130 | Axle ES D1 D9X124,8MM |

| 5 | TK413 | 911317105 | Axle MS D1 D9X114MM |

| 6 | TK414 | 911318002 | SU OPENER D1 |

| 6 | TK415 | 911318003 | SU OPENER D2 |

| 6 | TK457 | 740400000 | SU OPENER D1D12 12mm |

| 6 | TK458 | 740923000 | SU OPENER D2 12mm |

| 7 | TK416 | 911117177 | BAR BORES D9/11 MM |

| 7 | TK417 | 911117173 | BAR BORES D9/9 MM |

| 7 | TK418 | 911317208 | ROD |

| 7 | TK447 | 911317066 | ROD D11 |

| 8 | TK419 | 912518002 | LEVER |

| 8 | TK420 | 911118107 | LEVER |

| 9 | TK421 | 911118117 | CONNECTING BAR |

| 9 | TK422 | 911618002 | CONNECTING BAR |

| 10 | TK423 | 911217115 | SPRING |

| 10 | TK424 | 911317123 | SPRING 6,25X76,5 |

| 11 | TK425 | 911117155 | Sring Plate |

| 12 | TK426 | 911117170 | Ring half |

| 13 | TK427 | 911319118 | Feeder opener lever |

| 14 | TK428 | 911817054 | Projectile Lifter D1D12 D9mm |

| 14 | TK450 | 911817058 | Projectile Lifter D1D12 D12mm |

| 14 | TK448 | 911117146 | Projectile Lifter D1 D9mm |

| 14 | TK449 | 911817053 | Projectile Lifter D2 D9mm |

| 14 | TK451 | 911817063 | Projectile Lifter D2 D12 mm |

| 15 | TK429 | 911319117 | Drive axle D8/9,5/10/12x138 |

| 16 | TK430 | 911319847 | Feeder opener MS D1 |

| 17 | TK431 | 911319841 | Feeder opener D12-D2 Front |

| 18 | TK432 | 911319839 | Feeder opener D12-D2 rear |

| 19 | TK433 | 911319773 | Feeder opener ES D1(911119227) |

| 20 | TK434 | 911319224 | Feeder opener ES D12-D2 Rear |

| 20 | | 911319804 | Feeder opener ES D12-D2 Rear |

| 21 | TK436 | 911119306 | Feeder opener ES D12-D2 Front |

| 21 | | 911319803 | Feeder opener ES D12-D2 Front |

| 22 | TK438 | 911117172 | Splined Shaft |

| 22 | TK439 | 911117134 | Splined Shaft |

| 23 | TK440 | 912117145 | Bush |

| 23 | TK441 | 911717001 | Bush |

| 23 | TK442 | 911317193 | Bush 25,04/30/32x85,1 |

| 24 | TK443 | 911117154 | Sh lever |

| 25 | TK444 | 912526011 | Roller bolt |

| 26 | TK445 | 911619034 | Roller |

| 27 | TK446 | 911200217 | Disc |

| 28 | TK453 | 911119128 | CONNECTING ROD |

| 29 | TK454 | 911119285 | Special screw |

| 30 | TK455 | 911119283 | EH LEVER ES |

Engineered for Longevity and Performance

The projectile lifter is designed for extended service life, supporting up to 250,000 operational cycles, thanks to its high-grade alloy steel construction and heat-treated, CNC-machined precision. The component minimizes downtime with its robust wear resistance and stable performance, making it a reliable choice for demanding textile applications.

Compatibility and Customization

Tailored to fit Sulzer projectile loom models, this projectile lifter delivers optimal compatibility and effortless integration into your existing setup. Standard dimensions ensure broad applicability, while custom sizes can be manufactured to accommodate specific requirements, enhancing the versatility and performance of your weaving machinery.

Minimal Maintenance and Easy Installation

Precision engineering and high-quality materials allow this projectile lifter to function with minimal maintenance, reducing operational interruptions. Featuring a bolt-on or screw mount and metric fine thread, the part is designed for quick and straightforward installation, enabling efficient upgrades and replacements for loom operators.

FAQs of Projectile Lifter:

Q: How is the projectile lifter installed on Sulzer projectile looms?

A: The projectile lifter is designed for straightforward installation on Sulzer loom models using its bolt-on or screw mount with metric fine thread, ensuring secure and precise placement every time.Q: What benefits does the corrosion resistant coating provide?

A: The advanced corrosion resistant coating protects the lifter against rust and wear, extending its service life and ensuring consistent performance even in demanding textile environments.Q: When should I consider replacing the projectile lifter?

A: Replace the projectile lifter when signs of excessive wear are observed or after reaching approximately 250,000 operational cycles to maintain optimal loom performance and prevent unplanned downtime.Q: Where can I request custom sizes or order replacements?

A: Custom-sized projectile lifters and replacements can be requested through the importer or supplier in India, ensuring a tailored match for your specific loom requirements.Q: What is the typical usage of this projectile lifter?

A: This component is primarily used in Sulzer projectile looms for textile weaving, lifting projectiles reliably at high speedsup to 1200 picks per minutewith minimal noise and maintenance.Q: How does the CNC machining and heat treatment affect performance?

A: CNC machining and heat treatment provide precise dimensions and increased hardness (58-62 HRC), boosting durability, wear resistance, and ensuring the lifter withstands the mechanical stresses within high-speed weaving operations.Q: What are the main advantages of choosing this projectile lifter?

A: Key advantages include extended durability, high tensile strength, easy installation, minimal maintenance needs, corrosion resistance, and compatibility with automated, high-speed textile machinery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email