Weft End Gripper

Product Details:

- Thermal Conductivity Moderate

- Surface Finish Polished

- NO. Of Hole 2

- Tensile Strength High

- Automation Grade Automatic

- Mounting Type Direct Mount

- Size Standard (customizable on request)

- Click to View more

X

Weft End Gripper Price And Quantity

- INR

- Yes

- Universal for most Airjet and Rapier Looms

- Case Hardened

- Silver Grey

- Box / Polybag

- High

- Industrial Fabric Weaving

- Smooth

- Low

- Available

Weft End Gripper Product Specifications

- Automatic

- 2

- 55-60 HRC

- High

- Polished

- Approx. 150 mm x 20 mm x 15 mm

- Moderate

- Suitable for High-Speed Looms

- Approx. 15-20 mm (varies model-wise)

- Gripper

- 120 g (approximate)

- Rapier Loom

- Weft End Gripper

- Low

- Corrosion Resistant, Precision Engineered, Durable

- Loom Spare Part

- Standard (customizable on request)

- High Performance

- Industrial Textile Weaving

- Direct Mount

- Alloy Steel

- Yes

- Universal for most Airjet and Rapier Looms

- Case Hardened

- Silver Grey

- Box / Polybag

- High

- Industrial Fabric Weaving

- Smooth

- Low

- Available

Product Description

Having 13 years of experience, our organization is engaged in supplying flawless range of Weft End Gripper. It is manufactured with utmost perfection under diligent professionals by diligent experts with the aid of ultra-modern techniques. Due to its high quality and high tensile strength, the provided gripper is widely used for testing and increasing the strength of the hands. Our interested clients can purchase this Weft End Gripper is admired for its accurate dimensions.

Key points:

- Smooth edges

- Anti-corrosive surface

- Known for sturdiness

- Long life

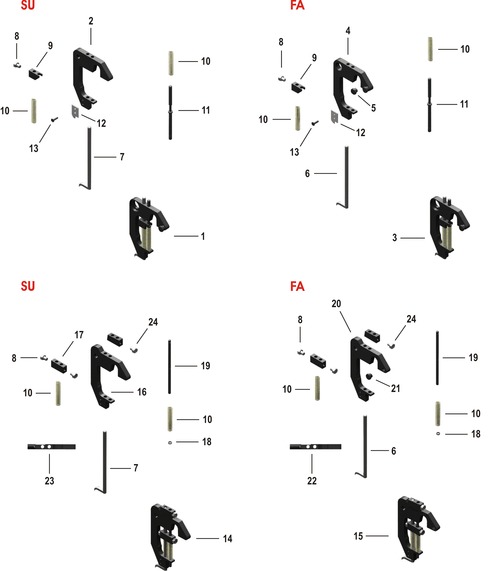

| ID: | TK No: | ART No: | Designation: |

| 1 | TK1203 | 911859344 | Gripper Su LLS hard spring knurled |

| 1 | TK1204 | 912536111 | Weft End gripper Su TLLS |

| 2 | TK1206 | 911659062 | Weft End Gripper Body Su |

| 2 | TK1207 | 911659067 | Weft End Gripper Body Su knurled |

| 3 | TK1209 | 911859268 | Weft End gripper Fa LLS |

| 3 | TK1210 | 911859275 | W.End gripper Fa LLS hard spring |

| 3 | TK1211 | 911859346 | Gripper Fa LLS hard spring knurled 14 |

| 3 | TK1212 | Grip.Fa Hard,knur. w.side plate 12-13-14 | |

| 3 | TK1213 | Gripper Fa Hard, w.side plate 4-12-13 | |

| 4 | TK1215 | 911859273 | Weft End Gripper Body FA |

| 4 | TK1216 | 911859290 | Weft End Gripper Body FA knurled-14 |

| 4 | TK1217 | Body Fa Hard,knur. w.side plate 12-13-14 | |

| 5 | TK1219 | 911232165 | Rivet Bolt (911 359 912) |

| 5 | TK1220 | Rivet Bolt for Modified body | |

| 6 | TK1221 | 911132290 | Foot Fa D:2,5 mm (911 359 602) |

| 6 | TK1222 | Foot Modified D:3 mm FA-SU | |

| 7 | TK1223 | 911132289 | Foot Su D:2,5 mm (911 359 601) |

| 8 | TK1225 | 911232168 | Special Screw |

| 9 | TK1226 | 911132167 | Guide piece |

| 10 | TK1228 | 911232169 | Spring |

| 10 | TK1229 | 911159292 | Spring Hard |

| 11 | TK1230 | 911236152 | Spring Rod L:50 |

| 11 | TK1231 | 911236164 | Spring Rod L:51 |

| 12 | TK1233 | 911359922 | Supporting Side plate |

| 13 | TK1234 | 921873346 | Rivet for S.side plate |

| 1 | TK1201 | 911859267 | Weft End gripper Su LLS |

| 1 | TK1202 | 911859274 | W.End gripper Su LLS hard spring |

Universal Compatibility and High Performance

Engineered to fit most airjet and rapier looms, the Weft End Gripper delivers reliable operation even in high-speed textile weaving environments. Its robust build and precision design ensure consistent fabric quality and reduced downtime, making it a vital component for industrial applications.

Corrosion Resistance and Durability

Featuring polished alloy steel construction, this gripper resists corrosion and wear, extending its service life in demanding weaving processes. The case-hardened surface increases hardness and durability while maintaining a smooth edge for optimum fabric handling.

Customizable and OEM Services

Available in standard dimensions and customizable sizes, the Weft End Gripper is adaptable to varied textile machinery needs. OEM services accommodate unique specifications, ensuring a tailored fit for specialized operations and streamlined supply for Indian importers and suppliers.

FAQs of Weft End Gripper:

Q: How does the Weft End Gripper enhance performance in high-speed looms?

A: The grippers precision-engineered design and high wear resistance optimize thread handling, enabling smoother and faster weaving. Its robust alloy steel construction supports sustained, efficient operations in high-speed looms.Q: What is the process for mounting the Weft End Gripper on textile machines?

A: It features a direct mount mechanism and smooth edge design, making installation straightforward. The standardized structure fits most airjet and rapier looms, allowing quick replacement and minimal machine downtime.Q: When should the Weft End Gripper be replaced during regular maintenance?

A: Thanks to its high durability and low maintenance requirements, replacement is only needed if wear is observed after extended use, typically coinciding with scheduled loom servicing to sustain optimal performance.Q: Where can customized sizes or OEM services for the Weft End Gripper be requested?

A: Customized sizes and OEM services can be arranged through authorized suppliers or importers in India. The manufacturer accommodates specific order requirements for tailored applications.Q: What are the key benefits of choosing a corrosion-resistant, case-hardened gripper for industrial weaving?

A: Corrosion resistance and case hardening significantly prolong the grippers working life, reduce maintenance costs, and ensure consistent performance under rigorous weaving conditions.Q: How is the Weft End Gripper packaged for delivery to ensure safety and integrity?

A: Each gripper is securely packed in either a box or polybag, providing adequate protection against shipping damage and maintaining product integrity until installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email