Projectile Brake

Product Details:

- Size Standard (as per machine requirements)

- NO. Of Hole 2-4 (Varies with Model)

- Capacity Designed for high-speed loom operation

- Noise Level Low

- Surface Finish Polished / Zinc Plated

- Features Wear Resistant, Corrosion Resistant, High Strength

- Mounting Type Bolt-on

- Click to View more

X

Projectile Brake Price And Quantity

- Yes

- Box packed with secure cushioning

- Low maintenance required

- Silver/Grey

- Universal fit for most projectile weaving machines

- 0°C to 80°C

- Mechanical

Projectile Brake Product Specifications

- 2-4 (Varies with Model)

- Standard (as per machine requirements)

- Brake Assembly

- Custom (varies with textile machine model)

- Approximately 200-350 g

- Projectile Loom

- Projectile Brake

- As per machine specification

- Bolt-on

- High-grade Alloy Steel

- High

- Wear Resistant, Corrosion Resistant, High Strength

- To control projectile movement and stop it with precision

- 48-52 HRC

- Low

- Moderate

- Designed for high-speed loom operation

- Manual

- Textile Machinery Spare Part

- Up to 1400 RPM

- Polished / Zinc Plated

- Yes

- Box packed with secure cushioning

- Low maintenance required

- Silver/Grey

- Universal fit for most projectile weaving machines

- 0°C to 80°C

- Mechanical

Product Description

Relying upon our highly developed infrastructure unit, we are engrossed in supplying a quality tested Projectile Brake. Finding application in the textile industry, the offered break is extensively demanded in weaving machine due to its rust resistance nature. Under the deft professionals' guidance, this break is manufactured using top grade materials with the aid of advanced machines. Furthermore, the provided Projectile Brake can be purchased from us in different dimensions at cost effective prices by our valued clients.

Key Points:

- Smooth finish

- High tensile strength

- Long lasting

- Rust resistant

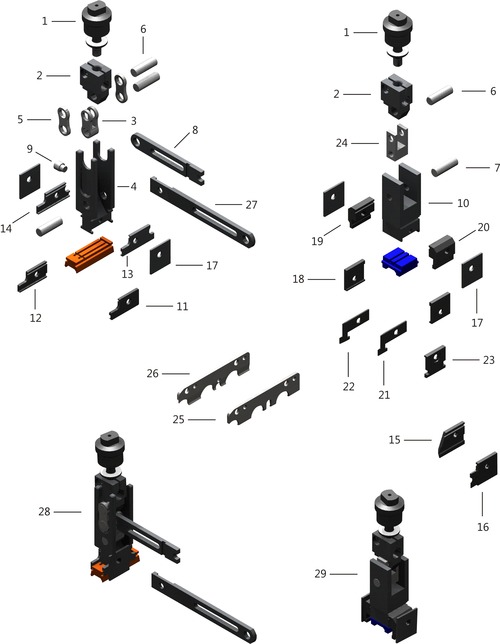

| ID: | TK No: | ART No: | Designation: |

| 1 | TK1801 | 911127151 | Threaded Pin G1/8" |

| 1 | TK1802 | 911827016 | Threaded Pin M12X0,5 Left |

| 1 | TK1803 | 911127186 | Threaded Pin M10x0,5 |

| 1 | | 911327338 | |

| 2 | TK1804 | 911127115 | Thread Block G1/8" |

| 2 | TK1805 | 911327184 | Thread Block M12X0,5 Left D10 |

| 2 | TK1806 | 911127182 | Thread Block M10X0,5 |

| 2 | TK1848 | 911327717 | Thread Block M12X0,5 Left D8 |

| 3 | TK1807 | 911127111 | Forked Link D8 |

| 3 | TK1845 | 911327227 | Forked Link D10 |

| 4 | TK1808 | 911827003 | Front holder of Brake D8 |

| 4 | TK1809 | 911827019 | Front holder of Brake D10 |

| 4 | TK1849 | 911827004 | Front holder of Brake D2 |

| 5 | TK1810 | 911127155 | Link D8 |

| 5 | TK1846 | 911327335 | Link D10 |

| 6 | TK1811 | 911327229 | Hollow Bolt D10X20 MM |

| 6 | TK1838 | 911227112 | Hollow Bolt D8X20 MM |

| 7 | TK1812 | 911327233 | Hollow Bolt D10x31,9 MM |

| 7 | TK1839 | 911227114 | Hollow Bolt D8x31,9 MM |

| 8 | TK1813 | 911127127 | Link |

| 8 | TK1814 | 911327284 | Bar |

| 9 | TK1815 | 911127157 | Pin |

| 10 | TK1816 | 911127118 | Rear Brake Holder |

| 10 | TK1817 | 911327306 | Rear Brake Holder |

| 11 | TK1818 | 911127166 | Front side plate D1 |

| 12 | TK1819 | 911127167 | Front side plate D1 |

| 13 | TK1820 | 911327351 | Front side plate D1 |

| 14 | TK1822 | 911327352 | Front side plate D1 |

| 15 | TK1821 | 911327013 | Front side plate D2 |

| 16 | TK1823 | 911327014 | Front side plate D2 |

| 17 | TK1824 | 911127171 | Holder Plate |

| 18 | TK1825 | 911127168 | Rear side plate |

| 19 | TK1826 | 911327393 | Rear side plate KS |

| 20 | TK1827 | 911327212 | Rear side plate WS |

| 21 | TK1828 | 911327021 | Front Guide plate K2 |

| 22 | TK1829 | 911327019 | Rear Guide plate K2 |

| 23 | TK1830 | 911327018 | Side plate K2 |

| 24 | TK1831 | 911327305 | Forked Piece D10 |

| 24 | TK1847 | 911127154 | Forked Piece D8 |

| 25 | TK1841 | 911327671 | Side plate D1 |

| 25 | TK1844 | 911327653 | Side plate D2 |

| 26 | TK1842 | 911327672 | Side plate D1 |

| 26 | TK1843 | 911327654 | Side plate D2 |

| 27 | TK1840 | 911327222 | Bar |

| 28 | TK1832 | 911827013 | Front Proj.Brake D1 PU |

| 28 | TK1833 | 912527015 | Front Proj.Brake D1 TW11 |

| 28 | TK1834 | 911827012 | Front Proj.Brake D2 PU |

| 29 | TK1835 | 911827014 | Rear Proj.Brake D1 |

| 29 | TK1836 | 912527016 | Rear Proj.Brake D1 |

| 29 | TK1837 | 911827033 | Rear Proj.Brake D2 |

Enhanced Performance for Textile Looms

Our Projectile Brake is tailored for universal compatibility, fitting most projectile weaving machines. Its robust mechanical design ensures efficient control of projectile motion, thus optimizing weaving precision and safety. Engineered with high-grade alloy steel and a polished or zinc-plated finish, it offers exceptional durability and consistent performance even during extended high-speed loom operations.

Reliable and Low Maintenance Design

Specifically crafted for textile machinery, this brake assembly demands minimal upkeep. It resists wear, oil, and grease thanks to its superior materials and construction. The manual, bolt-on installation is straightforward, supporting textile operators with reliable stopping power and quiet operation throughout intensive production cycles.

Secure Packaging and Custom Fit

To guarantee safe transit, each Projectile Brake is box-packed with protective cushioning. Its size, weight, and mounting hole options are customizable based on individual machine requirements, ensuring a precise fit and seamless integration into existing setups across Indian textile manufacturing environments.

FAQs of Projectile Brake:

Q: How is the Projectile Brake installed on different weaving machine models?

A: The Projectile Brake is a bolt-on component designed for universal fit across most projectile weaving machines. Custom diameters and 2-4 mounting holes (varying by model) allow easy alignment and secure installation following standard machine specifications.Q: What benefits does the mechanical brake design offer for high-speed loom operation?

A: Its mechanical construction delivers precise brake control, high strength, and reliability at speeds of up to 1400 RPM. The wear-resistant alloy steel provides consistent stopping performance, while the polished or zinc-plated finish ensures low noise and durability during rapid textile production.Q: When should the Projectile Brake be checked or maintained?

A: Routine visual inspections at scheduled intervals are recommended, but the brakes low-maintenance design means servicing requirements are minimal. Check periodically for signs of wear, especially if operating under maximum load or harsh conditions.Q: Where can this brake assembly be used within the textile industry?

A: The Projectile Brake is a universal textile machinery spare part, compatible with a wide range of projectile looms in weaving plants. Its high-performance features suit demanding Indian and international textile production environments.Q: What process should I follow if I need a customized size or diameter for my machine?

A: To obtain a brake assembly tailored to your machine, specify the required dimensions (L*W*H or diameter) and mounting hole count when placing your order. This ensures the brake aligns perfectly with your looms unique configuration.Q: How does the brakes resistance to oil and grease benefit daily operation?

A: The brakes resistance to oil and grease helps maintain optimal friction and braking efficiency over time. This increases lifespan, reduces cleaning frequency, and ensures continued safe operation even in environments where lubricants are used extensively.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email