Cushion Rubber

30000-35000 INR/Piece

Product Details:

- Features Shock Absorbent, Resilient, Wear Resistant

- Automation Grade Manual

- Mounting Type Press Fit / Fixed

- Noise Level Low

- Part Type Spare Part

- Tensile Strength Excellent

- Thermal Conductivity Moderate

- Click to View more

X

Cushion Rubber Price And Quantity

- 1 , , Piece

- 30000-35000 INR/Piece

Cushion Rubber Product Specifications

- Standard or as per requirement

- Smooth

- As per requirement

- High Durability

- Spinning, Weaving, Knitting

- Excellent

- Moderate

- Spare Part

- Low

- Press Fit / Fixed

- Cushion Rubber

- Manual

- Customized

- Shock Absorbent, Resilient, Wear Resistant

- Reduces Vibration, Increases Machine Life

- Lightweight

- Machine Cushion

Cushion Rubber Trade Information

- kolkata

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 500 , , Piece Per Month

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Manipur, Meghalaya, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Haryana, Uttar Pradesh, Gujarat, South India, Karnataka, North India, East India, Andhra Pradesh, Kerala, Central India, Chhattisgarh, All India

Product Description

We have been successfully involved in bringing a wide array of Cushion Rubber to our clients. It is equipped with a quality assorted material to increase its durability. In addition to this, provided rubber is used to work superbly on a smooth surface. Cushion Rubber is able to eliminate the chip issue. It allows a prolonged service life. It is also useful to give a great support and comfort to various objects or materials.

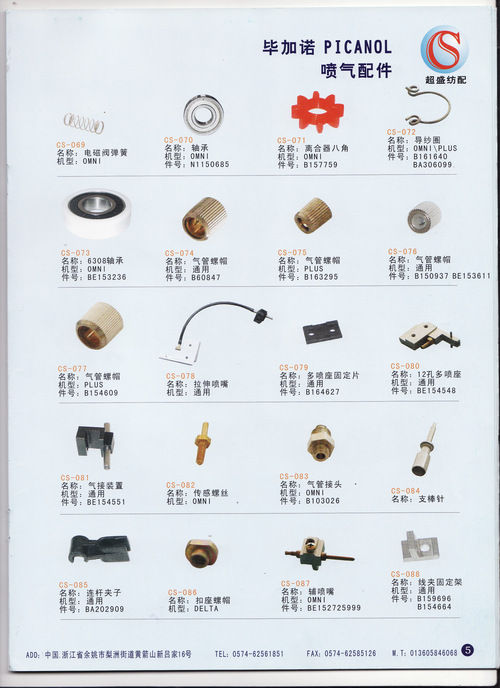

Picanol Airjet Loom Parts

Exceptional Durability & Versatility

This cushion rubber is crafted with resilience and high tensile strength, ensuring excellent performance even under demanding industrial conditions. Its composition allows it to withstand repeated stress, making it an ideal choice for a diverse range of textile and industrial machines, tailored in both size and specification as required by the application.

Optimized for Textile and Industrial Applications

Designed specifically for machinery such as spinning, weaving, and knitting equipment, our cushion rubber minimizes vibration, thereby enhancing both machine performance and longevity. Its strong bonding and smooth finish ensure secure installation and reduced wear over time, resulting in lower maintenance needs and consistent machine operation.

FAQs of Cushion Rubber:

Q: How is the cushion rubber installed in textile or industrial machinery?

A: The cushion rubber is mounted using either the press fit or fixed method, depending on your machinerys requirements. Precise dimensions can be customized for a seamless fit, ensuring robust support and shock absorption during machine operation.Q: What benefits does using this cushion rubber provide for textile machines?

A: Using this cushion rubber reduces vibration, resulting in smoother machine operation and decreased wear on machine components. This contributes to an extended machine life and lower maintenance costs, benefiting your production uptime and long-term efficiency.Q: When should I consider replacing the cushion rubber in my machinery?

A: It is advisable to inspect the cushion rubber regularly for signs of wear or decreased performance. Replacement is recommended if you observe reduced shock absorption, surface damage, or compromised adhesion, to maintain optimal machine efficiency.Q: Where can this cushion rubber be used in textile machinery?

A: This product is suitable for integration in spinning, weaving, and knitting machines. It can function as a spare part or a machine cushion, tailored to the specific points where shock absorption and vibration reduction are essential.Q: What is the process for customizing the size and dimension of the cushion rubber?

A: Simply provide your required length, width, height, or diameter specifications during the ordering process. Our team will manufacture the cushion rubber to those exact dimensions, ensuring a perfect fit for your machinery application.Q: What ensures the cushion rubbers strong adhesion and long service life?

A: This cushion rubber is produced with superior bonding materials and designed to exhibit low compression set and good elongation at break. These properties combine to provide excellent adhesion and resilience, even with frequent usage in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email