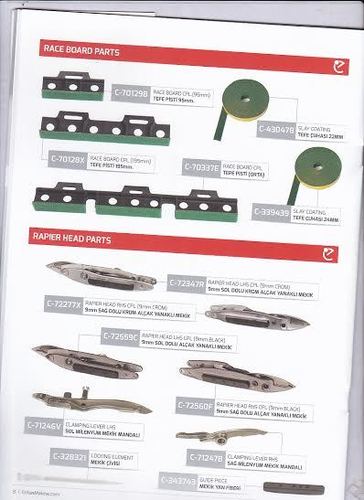

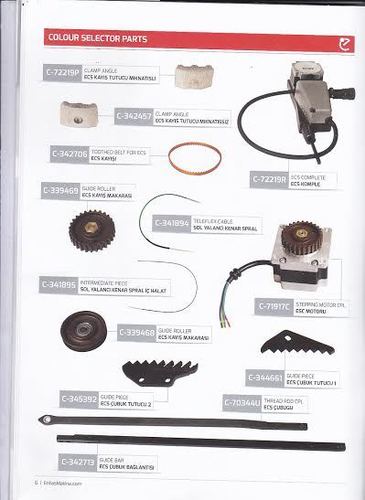

Colour Selector Parts

Product Details:

- Hardness 45-60 HRC

- Automation Grade Automatic/Semi-Automatic

- Features Corrosion Resistant, Precision Engineered, Durable

- Thermal Conductivity High (dependent on material used)

- Noise Level Low/Minimal

- Thread Type Metric / ISO Standard

- Tensile Strength 260-320 MPa

- Click to View more

X

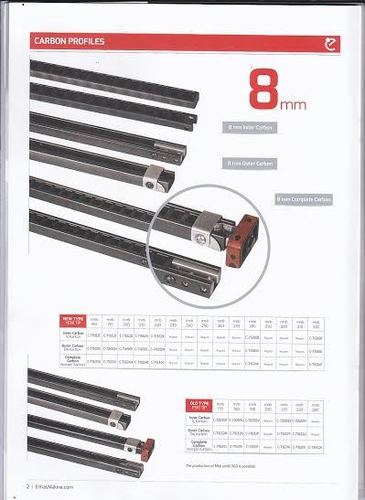

Colour Selector Parts Product Specifications

- 45-60 HRC

- 200-600 g (Approx)

- High (dependent on material used)

- Automatic/Semi-Automatic

- Corrosion Resistant, Precision Engineered, Durable

- Low/Minimal

- Bolt-On / Screw Fixing

- 260-320 MPa

- Colour Selector Parts

- Metric / ISO Standard

- Rapier Loom / Weaving Machine

- Suitable for High-Speed Weaving Machineries

- 2 to 6 (Model Based)

- Textile Loom Accessory

- Guiding and selecting thread colours in weaving machines

- Model Specific

- Replacement/Spare Part

- High-grade Aluminium Alloy / Engineering Plastic

- Dependent on Model (Typically 15-50 mm)

- Anodized / Powder Coated / Smooth Finish

- Up to 1200 RPM

- Standard/Custom

- -10°C to +80°C

- Secure industrial packaging

- Low maintenance required

- Excellent wear and friction resistance

- Fits leading textile machinery brands

- Available in multiple colour codes for machine compatibility

- For high efficiency colour selection in textile weaving

- Easy and quick to install

Product Description

Owing to our specialization in this domain, we are engaged in offering the best quality Colour selector parts. Finding a number of applications, these selectors are a complete electronic solution for airjet weaving looms & rapier weaving looms. The provided parts are manufactured as per the requirement of our clients with the aid of advanced machines under the direction of deft professionals. In addition to this, the offered Colour selector parts can be bought from us at rock bottom prices.

key Points:

- Lightweight

- Rigid in construction

- Excellent smooth finish

- Cost effective

Precision Matched for Textile Efficiency

Engineered for durability and precise function, our Colour Selector Parts excel in guiding and selecting thread colours in high-speed weaving environments. With options for various surface finishes and mounting types, these components deliver reliable performance and minimal wear, ensuring long operational life with low maintenance. Compatibility with standard textile machinery ensures a seamless integration process.

Versatile Material and Design Options

Select from robust aluminium alloys or high-performance engineering plastics, each offering excellent resistance to friction and corrosion. Available in anodized, powder coated, or smooth finishes, and compatible with both metric and ISO standard thread types, these selector parts accommodate a range of textile applications. Their customized dimensions and hole numbers suit specific machinery models, promoting versatile integration.

FAQs of Colour Selector Parts:

Q: How are Colour Selector Parts installed in weaving machines?

A: Colour Selector Parts are engineered for straightforward installation using either bolt-on or screw fixing methods. This design allows quick and secure attachment to most leading textile weaving and rapier loom machines, minimizing downtime during replacement or integration.Q: What makes these Colour Selector Parts suitable for high-speed textile operations?

A: These parts are crafted from high-grade materials that provide excellent wear and friction resistance, ensuring stable performance at speeds of up to 1200 RPM. Their robustness and precision engineering make them ideal for high-speed weaving environments.Q: When should I consider replacing a Colour Selector Part?

A: Replacement is recommended when signs of excessive wear, decreased colour selection accuracy, or increased noise levels are observed, ensuring consistent machine performance and fabric quality. Scheduled maintenance checks can help identify optimal replacement periods.Q: Where can I use these Colour Selector Parts?

A: They are designed for use in rapier looms and various weaving machines, compatible with many leading textile machinery brands, making them a versatile solution for textile manufacturers in India and global markets.Q: What maintenance is required for Colour Selector Parts?

A: These selector parts are low maintenance, requiring only periodic cleaning and inspection for wear as part of standard textile machinery upkeep. Their durable construction reduces the frequency and complexity of required maintenance tasks.Q: How do multiple colour codes benefit weaving operations?

A: Offering parts in multiple colour codes allows easy identification and integration, facilitating quick changes and compatibility with machine requirements. This enhances operational efficiency and minimizes errors in the colour selection process.Q: What are the benefits of choosing these as spare or replacement parts?

A: Precision engineered and manufactured to stringent quality standards, they offer high tensile strength, resistance to corrosion, and minimal noise, ensuring longer life spans and reliable performance for textile weaving operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email