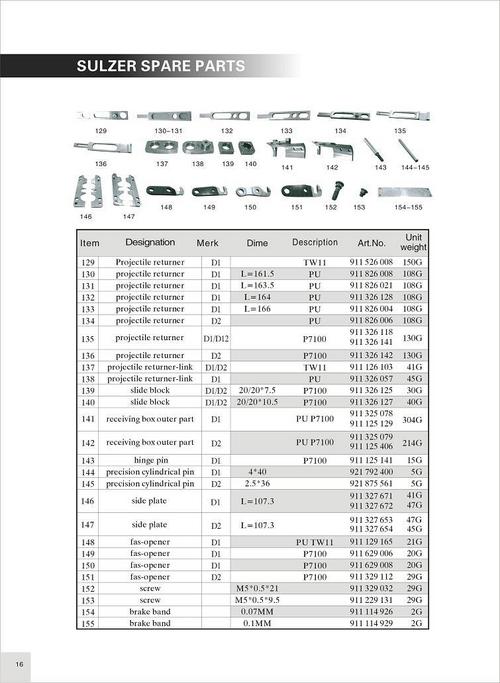

Sulzer Projectile Returner

Product Details:

- Noise Level Low

- Capacity Designed for continuous weaving operations

- NO. Of Hole As required by Sulzer model

- Thermal Conductivity Good (alloy steel property)

- Size Standard, as per Sulzer model compatibility

- Diameter Precision engineered (as per loom specification)

- Part Type Weaving Loom Accessory

- Click to View more

X

Sulzer Projectile Returner Price And Quantity

Sulzer Projectile Returner Product Specifications

- Standard, as per Sulzer model compatibility

- Projectile Returner

- Polished/Coated

- High, specific to Sulzer specs

- Precision engineered (as per loom specification)

- Weaving Loom Accessory

- Sulzer Projectile Loom

- As required by Sulzer model

- Projectile return mechanism in weaving

- Alloy Steel

- Designed for continuous weaving operations

- Low

- According to loom compatiblity

- Replacement Part

- Good (alloy steel property)

Product Description

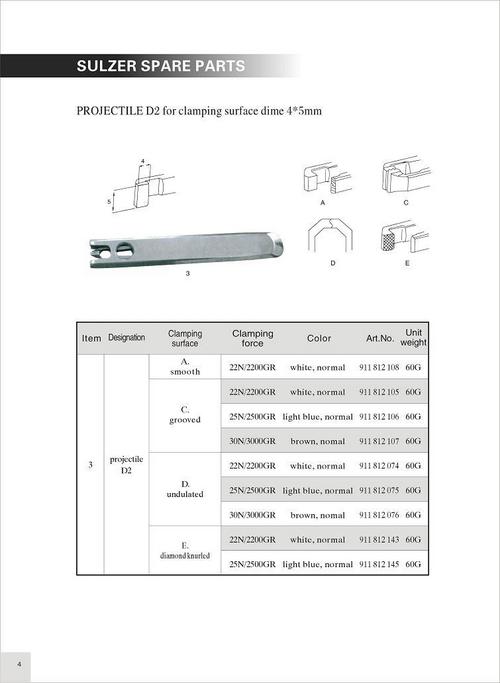

To meet the diverse requirements of our valued clients, we are engaged in offering fine grade Sulzer Projectile Returner. To ensure its fault free design, the provided product is manufactured quality tested basic materials at our highly advanced unit. Available in different specifications as per need of our valued patrons, this Sulzer Projectile Returner is perfect to be fitted into the loom machines.

Features:

- Lightweight and compact design

- Robust construction

- Corrosion resistance

- Convenient installation

Specification

| Usage/Application | Textile Industry |

| Packaging Type | Box |

| Size | 6 inch |

| Country of Origin | Made in India |

| Material | Metal |

| Shape | Rectangular |

| Surface Finish | Polished |

Unmatched Precision for Sulzer Looms

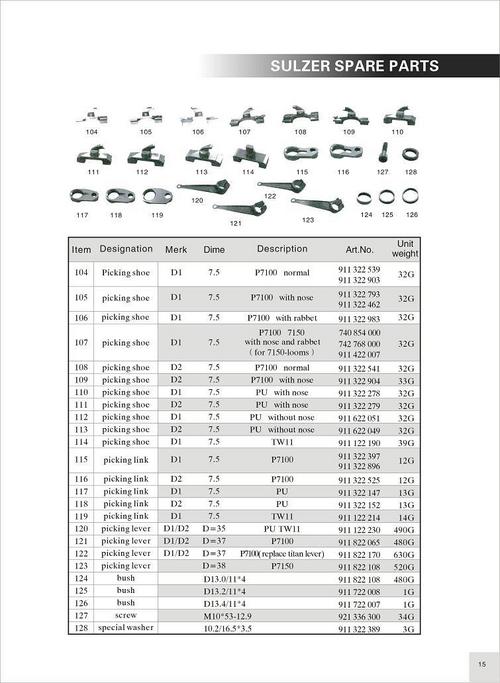

Our projectile returner is machined to exact OEM tolerances, ensuring a seamless fit and optimal functioning for Sulzer PU, TW11, and compatible projectile looms. With a precision-engineered diameter and the correct number of holes as required per model, it supports consistent textile production.

Durable and Corrosion Resistant

Manufactured using high-grade alloy steel and boasting a polished or coated finish, this returner is built to resist corrosion in humid, high-output textile environments. Its robust tensile strength upholds Sulzers reliability, even during continuous weaving shifts.

Flexible Packaging and Supply Options

Depending on user requirements, the Sulzer Projectile Returner is offered in both individual and bulk packing. This flexibility ensures suitability for both small-scale and industrial textile operations across India and beyond.

FAQs of Sulzer Projectile Returner:

Q: How does the Sulzer Projectile Returner improve weaving efficiency?

A: The projectile returner is engineered for continuous operation and precise OEM tolerances, minimizing downtime by ensuring smooth and reliable projectile returns, which contributes to consistent and efficient weaving.Q: What types of looms is this returner compatible with?

A: It is compatible with Sulzer PU, TW11, and other similar projectile looms, as it is produced according to standard Sulzer model specifications.Q: When should I consider replacing the projectile returner on my loom?

A: Replacement is recommended if you notice increased noise, inconsistent projectile return, or visible wear. Regular inspection ensures optimal loom performance and prevents unexpected breakdowns during weaving operations.Q: Where can I source the Sulzer Projectile Returner in India?

A: The Sulzer Projectile Returner is available through reputable importers and suppliers across India. Customers can order individually or in bulk, depending on their operational needs.Q: What process is used to manufacture the projectile returner?

A: The projectile returner is manufactured using CNC machining from alloy steel, finished with polishing or coating to enhance corrosion resistance and maintain precise dimensions as per Sulzer specifications.Q: How is the product packaged for delivery?

A: Packaging options include individual packing for smaller-scale requirements or bulk packaging for larger operations, ensuring product safety and convenience during transit.Q: What are the benefits of using a polished or coated surface finish?

A: A polished or coated surface finish enhances corrosion resistance, reduces friction during operation, and helps maintain lower noise levels, all critical for a smooth and long-lasting weaving process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email