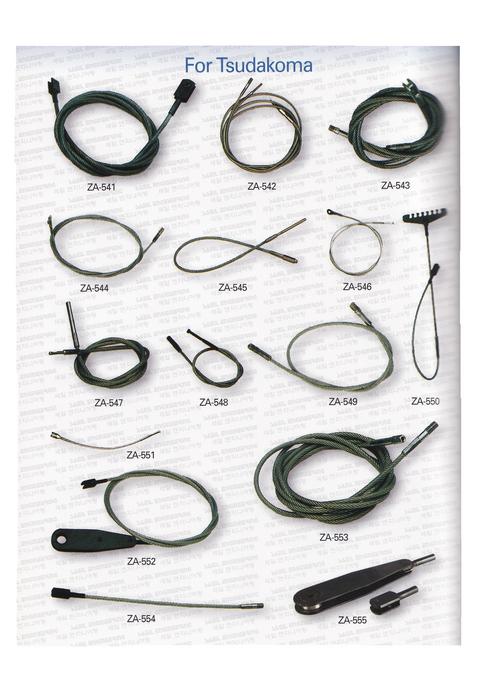

Tsudakoma Airjet Somnet Loom

500-3000 INR/Piece

Product Details:

- Automation Grade Automatic

- Thermal Conductivity Optimized for consistent operation under high temperatures

- NO. Of Hole Depends on heddle/reed configuration

- Tensile Strength Industrial standard tensile strength for longevity

- Features Energy efficient, advanced weft insertion, intelligent control, touch panel interface

- Mounting Type Floor mounted

- Hardness Enhanced hardness for moving components

- Click to View more

X

Tsudakoma Airjet Somnet Loom Price And Quantity

- 1 , , Piece

- 500-3000 INR/Piece

Tsudakoma Airjet Somnet Loom Product Specifications

- Enhanced hardness for moving components

- Loom main unit with accessories

- Approx. 2200kg3000kg (model dependent)

- Varies by model (typical: approx. 4100mm 1800mm 1700mm)

- Up to 1200 rpm (depends on model & yarn type)

- Complete Loom System

- Varied (customizable based on weaving width requirements)

- Dependent on reed & beam selections

- Automatic

- Industrial fabric production

- Weaving Machine

- Optimized for consistent operation under high temperatures

- Airjet Loom

- Depends on heddle/reed configuration

- Industrial standard tensile strength for longevity

- Energy efficient, advanced weft insertion, intelligent control, touch panel interface

- Floor mounted

Tsudakoma Airjet Somnet Loom Trade Information

- kolkata

- Cash in Advance (CID), Cash Advance (CA)

- 100 , , Piece Per Month

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Haryana, Kerala, Uttar Pradesh, South India, Madhya Pradesh, Karnataka, North India, Andhra Pradesh, Central India, Odisha, Jharkhand, West India, Chhattisgarh, All India

Product Description

Tsudakoma Airjet Somnet Loom. At our trusted vendors end, diligent professionals manufacture these parts by making utilization of premium quality raw material and highly-advanced technology in conformity with set industry norms of quality. Applicable in many textile industry for designing fabric, yarn or thread, this is broadly reckoned across the market due to anti-corrosive nature.

Features:

- Sturdiness

- High strength

- Corrosion resistance

- Easy to use

Advanced Control and Efficiency

The Tsudakoma Airjet Somnet Loom is built with an advanced digital electronic control system, featuring a diagnostic display and intelligent touch panel interface. This allows for precise operation adjustments, real-time monitoring, and swift diagnostics, ensuring maximized uptime and efficiency in textile manufacturing environments.

Versatile and Customizable

Supporting a wide range of weaving widths, from 190cm up to a customizable 280cm, this loom adapts to various fabric types and pattern requirements. The compatibility with different shedding motionscam, dobby, and electronic jacquardenables it to create complex patterns for apparel, home textiles, and industrial fabrics.

Low Maintenance and Reliability

Centralized automatic lubrication and a rigid structural frame are fundamental to the looms design. These features reduce the need for frequent manual maintenance and guarantee stable, vibration-minimized operation, even at high weaving speeds or under continuous production conditions.

FAQs of Tsudakoma Airjet Somnet Loom:

Q: How does the automatic weft sensor benefit the production process?

A: The automatic weft sensor detects yarn presence and immediately stops the loom in case of weft breakage, minimizing fabric wastage and ensuring consistent fabric quality during high-speed production.Q: What yarn types and weaving widths can the Somnet Series accommodate?

A: The loom is engineered to process a variety of yarns, including cotton, polyester, blends, and specialty types, across weaving widths of 190cm, 210cm, 230cm, and 280cm, with additional width customizations available upon request.Q: When is centralized automatic lubrication activated during loom operation?

A: The centralized system automatically engages at programmed intervals, ensuring all critical moving components receive adequate lubrication, enhancing longevity and reducing the risk of downtime.Q: Where can this model be utilized, and what are its main applications?

A: The Somnet Series is suitable for industrial settings and widely employed in the production of apparel, home textiles, and various industrial fabric applications due to its speed, flexibility, and structural robustness.Q: What is the process for integrating varied pattern designs into production?

A: With its electronically controlled weft storage and compatibility with cam, dobby, or jacquard shedding, operators can quickly program and switch among diverse fabric patterns directly from the looms control panel.Q: How does the looms structure contribute to operational benefits?

A: Its rigid frame minimizes vibration, which leads to enhanced fabric quality, stable high-speed performance, and longer machine life, particularly important in demanding industrial environments.Q: What are the key benefits of using this loom in terms of automation and energy efficiency?

A: Automatic functionssuch as intelligent control, real-time diagnostics, and efficient airjet weft insertionreduce manual labor, while energy-saving features lower operational costs, making the loom both productive and cost-effective for fabric manufacturers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email