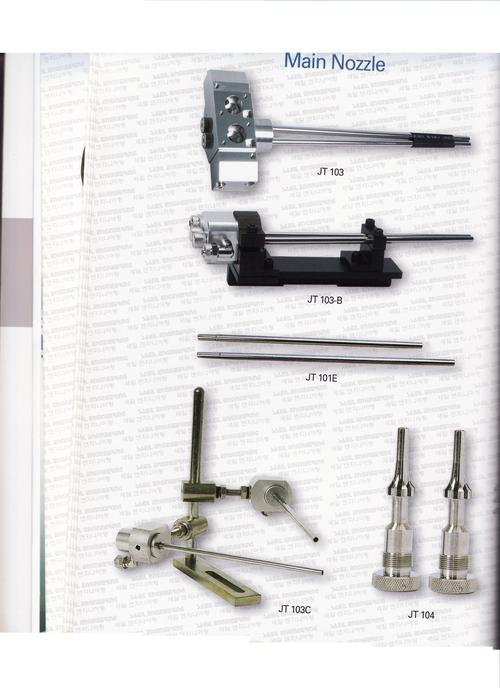

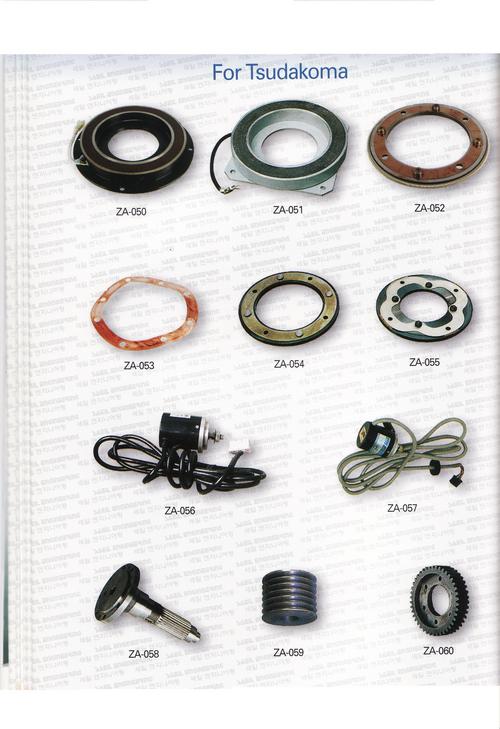

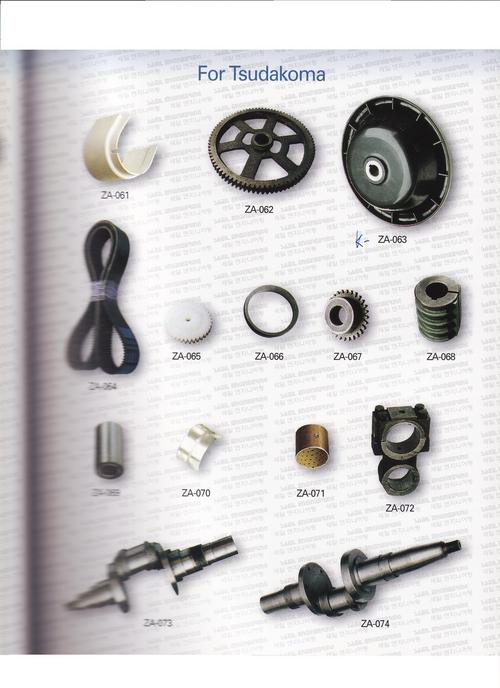

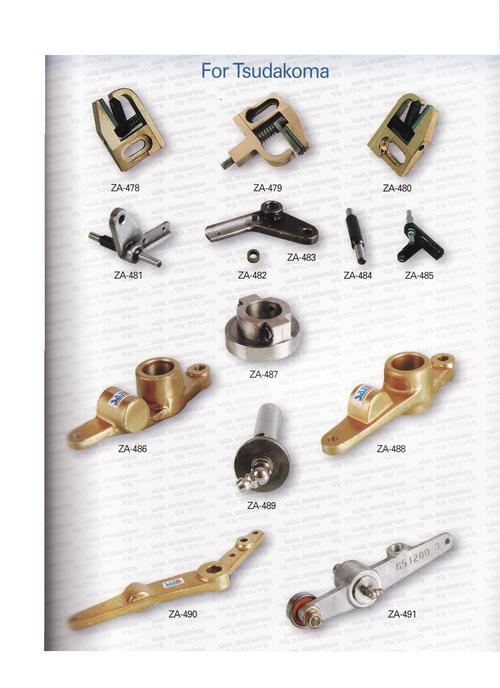

Tsudakoma Loom Spare Parts

Product Details:

- NO. Of Hole As per specific part design

- Capacity High durability for continuous operation

- Tensile Strength 650 MPa minimum

- Thermal Conductivity Standard for steel and engineering plastics

- Thread Type Metric, UNC, BSP as per part

- Noise Level Low

- Size Standard, custom sizes available

- Click to View more

X

Tsudakoma Loom Spare Parts Product Specifications

- Tsudakoma Air Jet and Water Jet Looms

- Standard for steel and engineering plastics

- 0.2 to 3 kg depending on item

- Metric, UNC, BSP as per part

- Low

- As per specific part design

- High durability for continuous operation

- 650 MPa minimum

- Tsudakoma Loom Spare Parts

- Loom Spare Part

- Varies by spare part

- Standard, custom sizes available

- Automatic

Product Description

We have been offering an excellent range of Tsudakoma Loom Spare Parts to our prestigious clients, since our emergence. Meeting the set industry standards, our offered parts are manufactured with the use of excellent quality raw materials and the contemporary techniques by our vendors. Owing to their outstanding features, the provided parts are specially preferred by the clients all across the country. Besides, we also test these Tsudakoma Loom Spare Parts on certain aspects in order to provide defect free range to the clients.

Features:

-

Dimensional accuracy

-

Corrosion resistance

-

Easy installation

-

Sturdy construction

Reliable Compatibility and Superior Performance

Each spare part is specifically designed to seamlessly fit Tsudakoma ZAX, ZA, and ZW model loom requirements. Options are available for both air jet and water jet applications, ensuring broad usability in weaving environments. The durable construction and precise thread types provide dependable performance, especially in high-volume operations.

Flexible Sizing and Packaging Solutions

Standard and customizable sizes meet the unique needs of textile manufacturers. All spare parts are carefully sealed in polyethylene or boxed in cartons to preserve quality during shipment. Custom orders are accommodated with tailored dimensions and fitting requirements, supporting a wide variety of textile machine setups.

Corrosion-Resistant, Heavy-Duty Construction

Surface treatments on each part grant them exceptional resistance to corrosion, extending the service life under demanding conditions. High tensile strength and optimal thermal conductivity contribute to sustained, efficient weaving, while low noise operation minimizes disruptions in production environments.

FAQs of Tsudakoma Loom Spare Parts:

Q: How do I ensure the Tsudakoma Loom Spare Parts will fit my specific loom model?

A: Each spare part is explicitly designed for Tsudakoma ZAX, ZA, and ZW model looms. Detailed specifications are available for both air jet and water jet loom applications. For custom sizes or unique configurations, you can provide your looms details to the supplier for tailored compatibility.Q: What is the process for ordering genuine OEM versus aftermarket spares?

A: You may request either genuine OEM components or high-quality aftermarket versions based on your plants requirements. The supplier will confirm availability and can suggest the best fit according to operational demands and maintenance preferences. Both options maintain strict manufacturing standards.Q: When can I expect delivery after placing an order for spare parts?

A: Lead times for Tsudakoma Loom Spare Parts range from immediate dispatch for in-stock items to two weeks for parts requiring sourcing or customization. Your order timeline will be confirmed during the procurement process, ensuring minimal disruption to production.Q: Where are these spare parts typically applied in the textile sector?

A: These parts are widely used in weaving mills, textile plants, and industrial fabric manufacturing facilities across India. Their robust construction and tailored design make them suitable for continuous operation in large-scale textile environments.Q: What is the benefit of corrosion-resistant, machined metal spare parts for looms?

A: Corrosion resistance, achieved through treated surfaces, prolongs the lifespan of each component under humid or abrasive conditions. Combined with high tensile strength and reliable painted or plated finishes, this ensures consistent operation and reduced replacement frequency.Q: How do I know which thread type and size are right for my application?

A: Thread typesMetric, UNC, or BSPare specified according to each parts design. Standard sizes are readily available, while custom sizing can be provided on request. Reference your looms manual or consult the supplier to select the perfect match for your machine.Q: What usage advantage do Tsudakoma loom spare parts offer in automated textile operations?

A: Engineered for automatic-grade application, these spares deliver quiet performance, steady durability, and high operational capacity, making them ideal for seamless functioning in modern, automated textile processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email