Projectile Loom Spare Parts

Product Details:

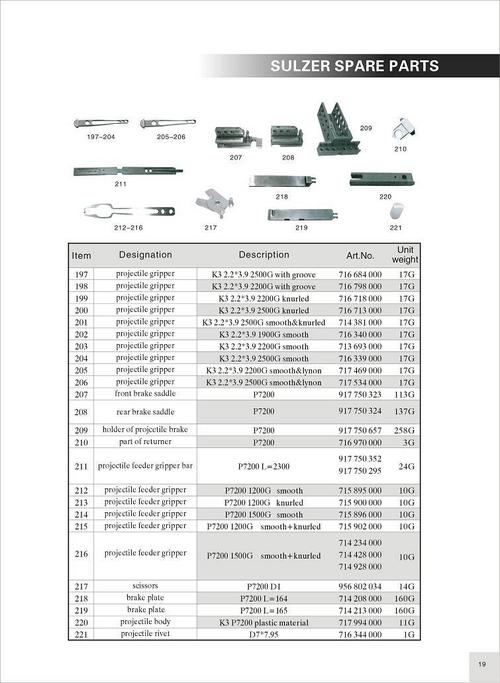

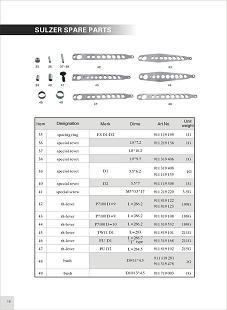

- Part Type Projectile, Feeder, Gripper, Guide, Picker, Cam, Lever, Bush

- Noise Level Low

- Diameter As per OEM or Drawing

- Features Corrosion Resistant, Precise Dimensions, Robust Construction

- Thread Type Metric/Fine Thread (where applicable)

- Surface Finish Smooth/Polished/Coated

- Capacity High Load Bearing

- Click to View more

X

Projectile Loom Spare Parts Product Specifications

- Corrosion Resistant, Precise Dimensions, Robust Construction

- Projectile Loom Spare Parts

- Replacement Part

- As per OEM or Drawing

- 14 (Depending on part)

- Standard/Customizable

- Smooth/Polished/Coated

- High Load Bearing

- Alloy Steel/Cast Iron/Stainless Steel

- Weaving/ Textile Manufacturing

- 0.12.5 kg (Depending on Part)

- Metric/Fine Thread (where applicable)

- As per Drawing/OEM

- Projectile Loom (Sulzer, Dornier, Somet, etc.)

- Suitable for Looms up to 1200 RPM

- Low

- Projectile, Feeder, Gripper, Guide, Picker, Cam, Lever, Bush

Product Description

Our quality committed firm has attained the topmost position in this field by putting forth top grade Projectile Loom Spare Parts. By utilizing optimal quality basic materials, the offered parts are manufactured under the stern supervision of diligent professionals. These parts are available in different sizes, designs and finishes as peer need of our valued patrons. The provided Projectile Loom Spare Parts are highly appreciated among clients for their sturdiness and dimensional accuracy.

Features:

- Bent proof

- Longer life

- Anti-corrosive

- Easy to install

Superior Material and Finish

Our spare parts are manufactured using high-grade alloy steel, cast iron, or stainless steel, ensuring longevity and consistent quality. Each component undergoes heat treatment and precision machining to deliver a smooth, polished, and coated surface for maximum corrosion resistance and low noise operation.

Tailored Compatibility and Precise Fit

Designed for Sulzer, Dornier, Somet, and other major projectile loom brands, our replacement parts conform to original equipment manufacturers specifications. With customizable sizes and thread types, these components guarantee outstanding compatibility and high load-bearing capacity in textile manufacturing settings.

FAQs of Projectile Loom Spare Parts:

Q: How are the projectile loom spare parts packaged and shipped to ensure safe delivery?

A: Parts are securely packed in boxes or cartons, with packaging tailored to customer requirements. This ensures protection during transit and delivery, maintaining quality upon arrival.Q: What types of loom brands are these spare parts compatible with?

A: These replacement parts are compatible with major projectile loom brands, including Sulzer, Dornier, Somet, and other established manufacturers. Compatibility is ensured by adhering to OEM specifications and dimensions.Q: When should I consider replacing my looms components with these spare parts?

A: Replacement is recommended when parts show signs of wear, corrosion, or reduced performance. Regular maintenance and timely replacement help sustain optimum weaving speeds and machine efficiency.Q: Where can these spare parts be used within the textile manufacturing process?

A: These components are deployed in weaving operations within textile mills, predominantly in projectile looms. They support various functions such as guiding, gripping, picking, and feeding.Q: What is the process involved in customizing projectile loom spare parts?

A: Customization is based on OEM drawings or specific technical requests. Precision machining (tolerance up to 0.01 mm) allows tailoring diameter, dimensions, thread type, hole numbers, and surface finish to suit unique applications.Q: How does corrosion resistance benefit these loom spare parts?

A: Enhanced corrosion resistance prolongs component life, reduces maintenance frequency, and ensures reliable operation in humid or challenging production environments, resulting in cost savings and improved productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email