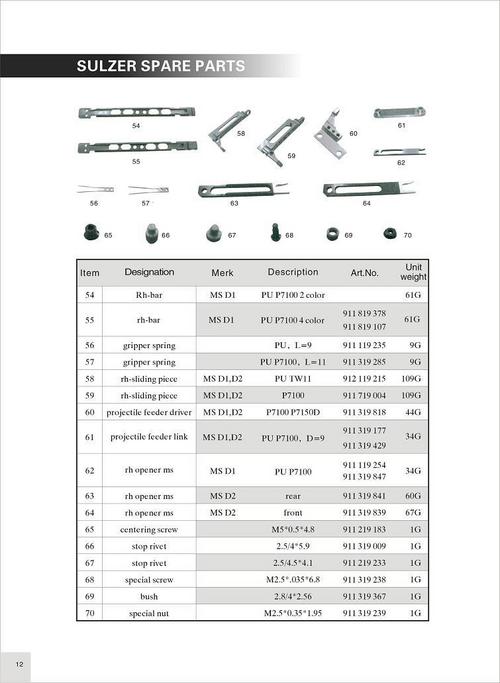

Sulzer Gripper Spring

Product Details:

- Diameter As per OEM standard

- Noise Level Low

- Size Standard/Custom as per requirement

- Surface Finish Polished

- Capacity Designed for Sulzer gripper mechanism

- Automation Grade Manual/Automatic

- Part Type Textile Machine Spare Part

- Click to View more

X

Sulzer Gripper Spring Price And Quantity

Sulzer Gripper Spring Product Specifications

- Low

- As per OEM standard

- Weaving Machine Gripper Mechanism

- Standard/Custom as per requirement

- Polished

- Low

- Designed for Sulzer gripper mechanism

- Textile Machine Spare Part

- Manual/Automatic

- Gripper Spring

- Sulzer Loom

- Direct Mount

- Rust resistant, Durable, Precise dimensions

- High Carbon Steel

- As per OEM specification

- Up to 1800 MPa

- Gripper Arm Spring

Product Description

We are remarkable name in this domain, engrossed in providing top-notch grade Sulzer Gripper Spring. This spring is manufactured using quality tested basic materials at sophisticated unit. Used as loom, the offered spring is ideal for installing tin stitching machines. This spring is highly acclaimed for its lightweight and compact design. In addition to this, the provided Sulzer Gripper Spring is available in different sizes, shapes and other specifications to meet the need of our valued clients.

Key points:

- User friendly design

- Easy to fix

- Perfect finish

- Accurate dimension

Superior Durability and Strength

Manufactured from high carbon steel and designed with cold-coiling technology, the Sulzer Gripper Spring excels in durability and tensile strengthcapable of reaching up to 1800 MPa. Its polished, rust-resistant surface guarantees longevity, even in rigorous textile environments. This ensures stability and optimum performance in Sulzer gripper mechanisms.

Perfect OEM Compatibility and Customization

Each gripper spring is meticulously crafted for seamless compatibility with Sulzer loom models. Whether you require standard dimensions or custom specifications, these springs conform to OEM standards for secure fitting and reliability. Their precise engineering addresses the specific needs of diverse weaving machines and gripper requirements.

FAQs of Sulzer Gripper Spring:

Q: How does the Sulzer Gripper Spring benefit Sulzer loom weaving machines?

A: This gripper spring provides outstanding durability, rust resistance, and reliable tension to the gripper mechanism, ensuring smooth, uninterrupted weaving operations in Sulzer looms. Its design minimizes downtime and maintains product quality.Q: What is the installation process for the Sulzer Gripper Spring?

A: The spring is designed for direct mounting, allowing for straightforward replacement or installation. No special tools are required, and it fits securely according to OEM specifications for Sulzer textile machines.Q: When should the Sulzer Gripper Spring be replaced?

A: Replacement is recommended if you observe loss of tension, visible wear, or reduced performance in your weaving machines gripper mechanism. However, due to its robust construction and high corrosion resistance, it requires minimal maintenance and rarely needs frequent replacement.Q: Where is the Sulzer Gripper Spring primarily used?

A: This component is primarily used in Sulzer gripper mechanisms within weaving machines for textile manufacturing, especially those operating on Sulzer loom systems. It is tailored for both manual and automated setups.Q: What usage recommendations do you have for optimal performance?

A: To ensure optimal performance, use the spring as per OEM-specified dimensions and within its designed capacity. Regular inspection for physical integrity and correct mounting enhances durability and weaving consistency.Q: How does its manufacturing technique contribute to its quality?

A: The cold-coiling manufacturing technique ensures uniform tension, precise dimensions, and a robust structure, which collectively improve the springs reliability and extend its lifespan amidst demanding textile operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email