Sulzer Projectile Feeder Parts

Product Details:

- NO. Of Hole Multiple, as per design specification

- Surface Finish Galvanized / Polished / Coated

- Tensile Strength Up to 1200 MPa

- Automation Grade Automatic

- Diameter Customized as per feeder model

- Thread Type Metric

- Noise Level Low

- Click to View more

X

Sulzer Projectile Feeder Parts Price And Quantity

Sulzer Projectile Feeder Parts Product Specifications

- Metric

- Customized as per feeder model

- Automatic

- Up to 1200 MPa

- For precise weft insertion in weaving

- Designed for high speed operation

- Galvanized / Polished / Coated

- Projectile Feeder Parts

- Multiple, as per design specification

- Projectile Feeder

- Vary by specific feeder part; refer to drawing

- Sulzer Projectile Loom

- Hardened Alloy Steel, Engineering Plastic

- Low (suited for mechanical stability)

- Lightweight to moderate, based on part

- Standard, as per Sulzer loom model requirement

- Low

Product Description

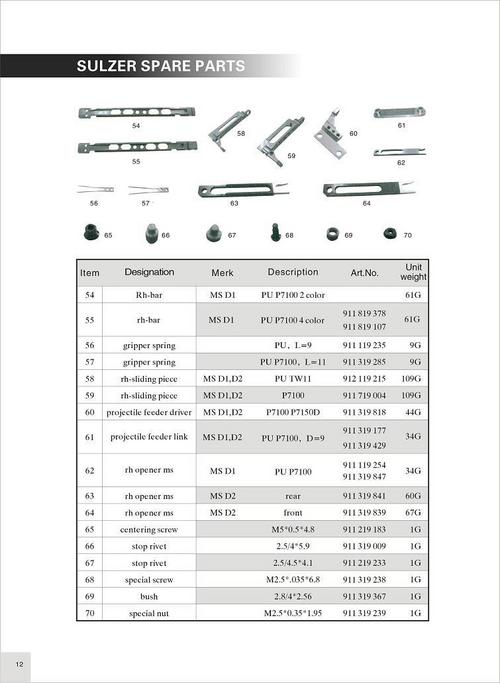

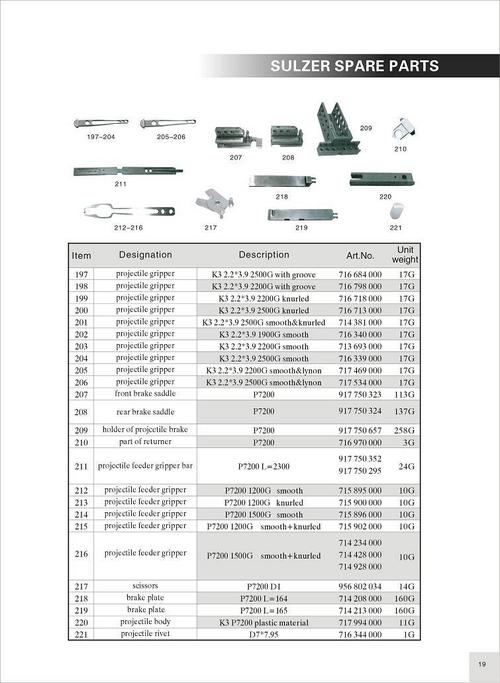

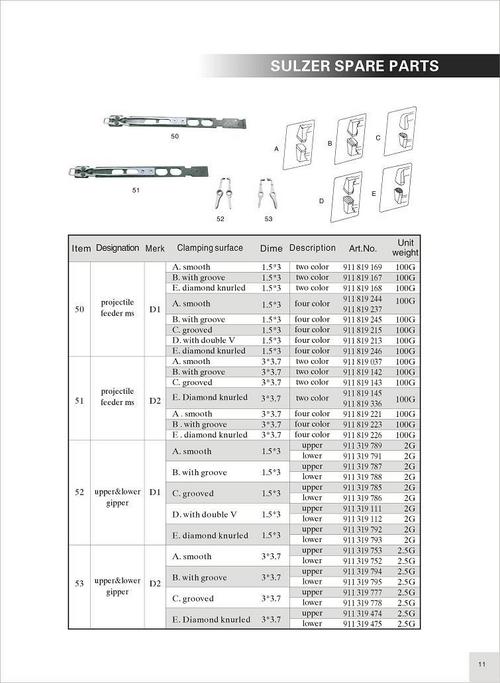

Since 2004, we have been engaged in offering the finest grade Sulzer Projectile Feeder Parts. These parts are manufactured under the strict guidance of dedicated professionals at our highly advanced unit. The provided parts are ideal for stitching machine sizes and looms. Find application textile industry, these Sulzer Projectile Feeder Parts are highly recognized for their rust proof nature.

Features:

- Seamless finish

- Sturdiness

- Long life

- Easy installation

Specification

- Brand Name : Sulzer Rapier

- Use : Used In Textile Or Garment Machines For Manufacturing Loom, Fabric And Yarn

- Usage : Textile Industry

- Material : Metal

- Installation : Easy

Superior Durability and Corrosion Resistance

Designed for long-lasting performance, these Sulzer projectile feeder parts feature advanced heat treatment and are made from hardened alloy steel or high-grade engineering plastics. Their galvanized, coated, or polished finishes ensure high corrosion resistance, making them reliable even in humid environments. This durability minimizes machine downtime and maintenance cost in textile weaving operations.

Optimal Performance and Compatibility

Each projectile feeder part is CNC machined or precision moulded for accuracy and consistently high quality. Compatible with a range of Sulzer loom models (PU, TW11, P7100, P7200), these components can be used as OEM or aftermarket spares. They allow seamless integration for textile weaving units and mills, ensuring optimum efficiency and precise weft control in high-speed production.

FAQs of Sulzer Projectile Feeder Parts:

Q: How do I determine which Sulzer projectile feeder part is compatible with my loom model?

A: To select the correct feeder part, refer to your looms modelsuch as PU, TW11, P7100, or P7200and consult the standard sizing. For added accuracy, you may request the OEM reference number and compare the technical drawings to ensure proper fit and function within your weaving unit.Q: What benefits does the corrosion resistance offer in humid textile environments?

A: The high corrosion resistance, owing to galvanized, polished, or coated surfaces, protects feeder parts from rust and wear in humid conditions. This feature prolongs component life, reduces maintenance needs, and ensures reliable, uninterrupted weaving operations.Q: When should I replace a Sulzer projectile feeder part?

A: Replacement is necessary if you observe decreased weft insertion accuracy, increased machine noise, or visible signs of wear and corrosion. Periodic inspections and adhering to scheduled maintenance intervals help prevent unexpected downtime in your weaving process.Q: Where are these projectile feeder parts primarily used?

A: These parts are specifically designed for textile weaving units and mills using Sulzer projectile loomslike the PU, TW11, P7100, and P7200 modelsacross India. Their high compatibility ensures they can be easily sourced and integrated by textile machinery importers and suppliers.Q: What is the manufacturing process for these feeder parts?

A: Each part is either CNC-machined or precision-moulded from hardened alloy steel or engineering plastic, then heat-treated for enhanced strength. All components undergo individual inspection and calibration to ensure adherence to rigorous quality standards.Q: How does the design contribute to high-speed operation and low noise levels?

A: The lightweight yet robust construction, enhanced surface finish, and precise engineering minimize friction and mechanical resistance, supporting high-speed operation. Additionally, the parts are designed to reduce operational noise, promoting a quieter weaving environment.Q: What is the main advantage of using OEM and aftermarket compatible feeder parts?

A: Interchangeable design allows easy replacement with both original and aftermarket components. This flexibility offers convenience, reduces downtime, and helps maintain optimal loom performance without compromising quality or compatibility.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email