Sulzer Projectile Feeder Plate

Product Details:

- Noise Level Low (<50 dB)

- Tensile Strength Above 800 MPa

- Thread Type No Thread

- NO. Of Hole 6

- Part Type Replacement Spare

- Capacity Optimized for continuous textile feeding

- Size Standard (as per Sulzer model specification)

- Click to View more

X

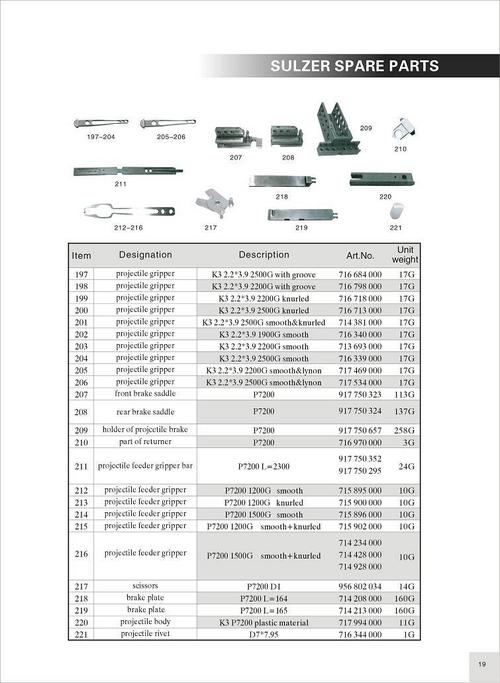

Sulzer Projectile Feeder Plate Product Specifications

- Optimized for continuous textile feeding

- No Thread

- Above 800 MPa

- Sulzer Projectile Loom

- Low (<50 dB)

- Projectile Feeder Plate

- Replacement Spare

- 6

- Moderate (suitable for industrial textile operation)

- Weaving machine projectile feeding

- Standard (as per Sulzer model specification)

- 220 g (approximate)

- 68 mm (approximate)

- 100 mm x 68 mm x 8 mm (approximate)

- Feeder Plate

Product Description

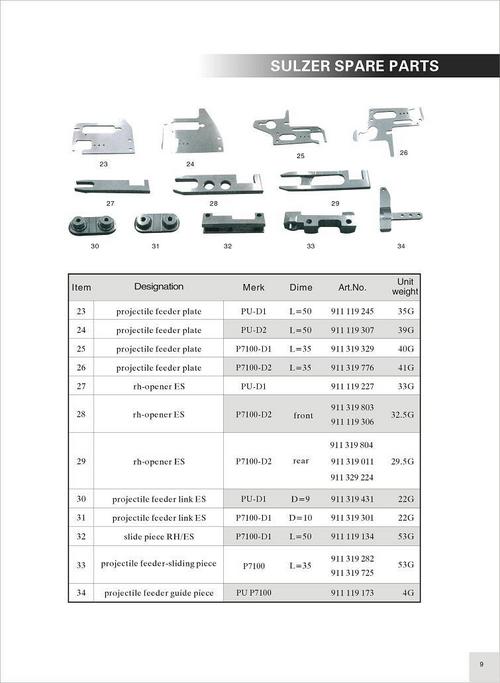

Being a top notch firm, we are actively engrossed in rendering a wide ambit of Sulzer Projectile Feeder Plate. It is equipped in a hot rolled technique to withstand the heavy loading challenges. Therefore, provided plate is used in textile industries. Sulzer Projectile Feeder Plate is easy to engraved into a trough as well as projectile picking solution. It has a metal shift material which can utilized for a longer time without any trouble.

Sulzer Projectile Feeder Plate

Engineered Precision for Weaving Efficiency

Manufactured with tight machining tolerances of 0.01 mm and a chamfered edge, this feeder plate offers consistent alignment and reduced wear, enhancing your Sulzer looms efficiency. Its robust design also minimizes operational noise, supporting quieter textile production environments.

Built to Endure Industrial Conditions

With high corrosion resistance and a tensile strength surpassing 800 MPa, this feeder plate stands up to rigorous and continuous usage. Its metallic finish not only provides durability but also helps maintain performance in demanding weaving operations.

Optimized Compatibility and Easy Installation

Designed specifically for Sulzer PU, TW, P7100, and P7200 models, installation is straightforward, requiring no threading. The standardized dimensions ensure a seamless fit, so maintenance teams can replace parts swiftly and reduce machine downtime.

FAQs of Sulzer Projectile Feeder Plate:

Q: How does the Sulzer Projectile Feeder Plate benefit weaving machine operations?

A: The feeder plate enables smooth, continuous projectile feeding while maintaining low noise levels and minimizing operational interruptions. Its high corrosion resistance and mechanical strength enhance machine longevity and weaving efficiency.Q: What types of Sulzer loom models are compatible with this feeder plate?

A: This spare part is compatible with Sulzer PU, TW, P7100, and P7200 projectile looms, conforming to their standard size and technical specifications.Q: When should I replace the feeder plate on my Sulzer projectile loom?

A: Replacement is recommended during scheduled maintenance or if you notice irregular feeding, visible wear, or increased noise, as these indicate potential plate degradation affecting performance.Q: Where can I purchase the Sulzer Projectile Feeder Plate in India?

A: You can acquire this feeder plate from authorized importers and suppliers specializing in Sulzer loom spares and components within the Indian textile machinery market.Q: What is the installation process for this feeder plate?

A: Installation is straightforward due to its standard, threadless design. The component is simply positioned and secured as per the loom model specifications; no special threading or modifications are required.Q: How is this feeder plate packaged and delivered?

A: Each plate is individually packed in a poly pack to ensure protection against physical damage and corrosion during storage and shipment.Q: What features contribute to the longevity of this feeder plate in textile operations?

A: Its high tensile strength, corrosion-resistant metallic finish, and dimensional accuracy help the plate withstand harsh industrial conditions, frequent use, and prolonged textile production cycles.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email