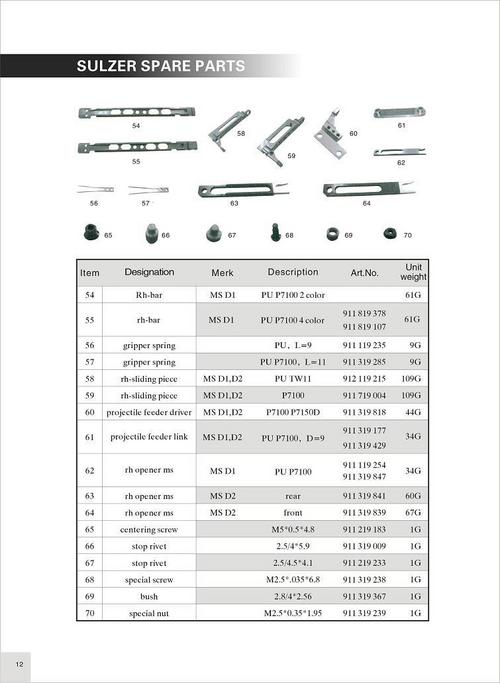

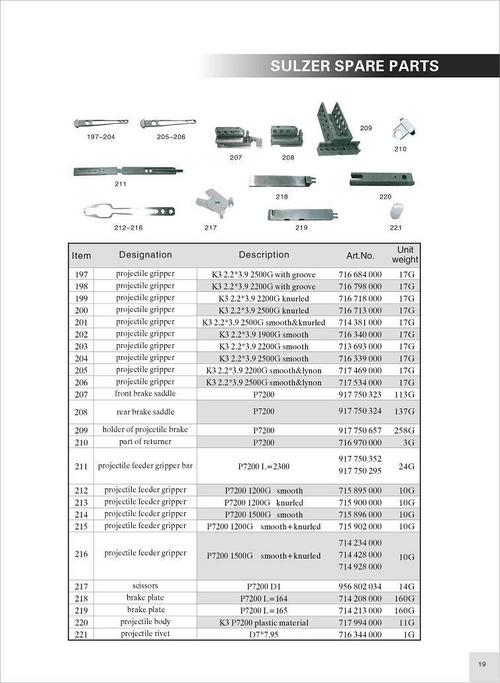

Sulzer Projectile Gripper Feeder

Product Details:

- Part Type Spare Part / Feeder Component

- Thermal Conductivity Medium (stable for textile environmental demands)

- NO. Of Hole As per model specification

- Tensile Strength High (suitable for textile load requirements)

- Automation Grade Automatic

- Mounting Type Direct Mount

- Diameter Dependent on loom model

- Click to View more

X

Sulzer Projectile Gripper Feeder Product Specifications

- Designed for continuous industrial operation

- Dependent on loom model

- Sulzer Projectile Loom

- Model specific / Available on request

- Standard (Compatible with Sulzer looms)

- Alloy Steel

- Low

- High durability, Precise projectile feeding, Easy to install

- Gripper Feeder

- Automatic

- High (suitable for textile load requirements)

- Projectile Gripper Feeder

- Spare Part / Feeder Component

- Medium (stable for textile environmental demands)

- As per model specification

- Industrial Weaving / Loom Operation

- Direct Mount

Product Description

To meet the diverse requirement of our valued patrons, we are engrossed in offering excellent grade Sulzer Projectile Feeder Gripper. With the aid of innovative techniques, the provided product is manufactured under the strict guidance of ingenious professionals. This product is highly cherished among industries due to its corrosion proof nature and seamless finish. Apart from this, the offered Sulzer Projectile Feeder Gripper is suitable for textile as well as garments industrial applications.

Features:

- Easy to carry

- Bent resistant

- Long life

- Flawlessness

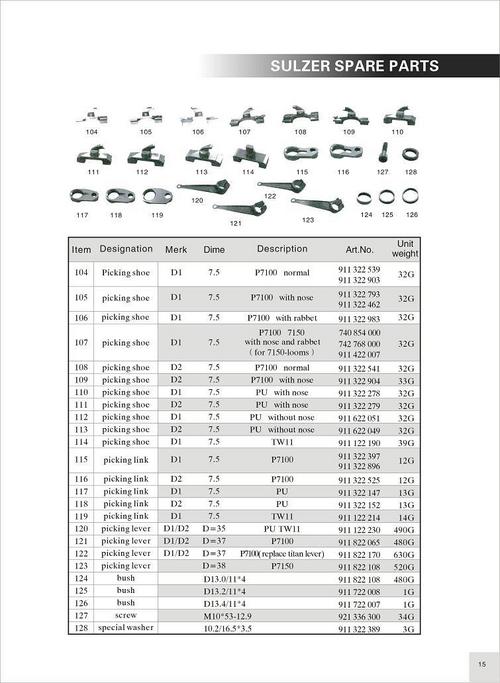

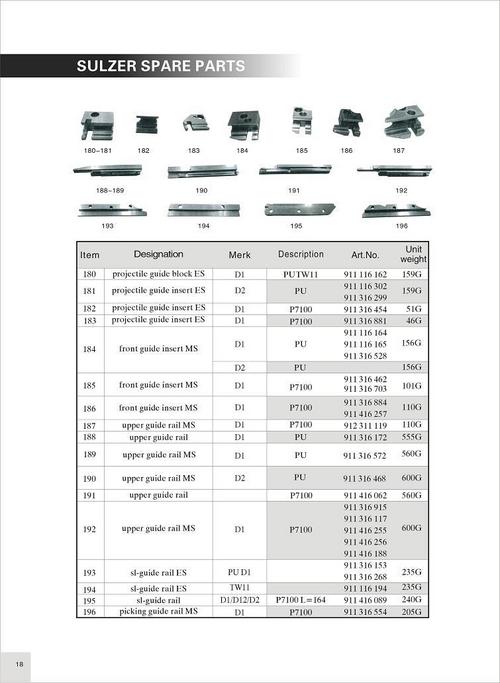

Engineered for Seamless Compatibility

Our gripper feeder is compatible with Sulzer PU, TW11, P7100, and most major Sulzer projectile loom models. The standard size and model-specific options provide seamless integration, reducing downtime and ensuring reliable operation across various machine configurations.

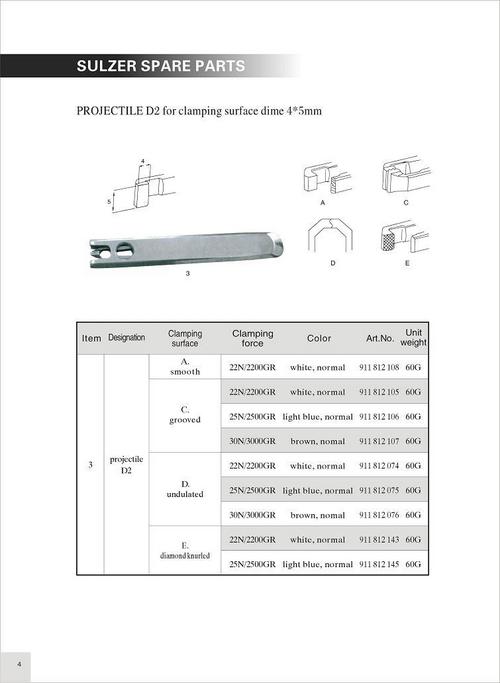

Precision and Durability for Industrial Weaving

Constructed from high-strength alloy steel, the feeder delivers outstanding tensile strength and wear resistance, engineered to endure up to 1 million operating cycles. Its precise design ensures optimal projectile feeding, while medium thermal conductivity safeguards stability across changing textile production environments.

User-Friendly Installation and Low Maintenance

Direct mounting and ergonomically crafted fitting simplify installation, making it easy to replace or upgrade. With a low maintenance requirement, periodic lubrication extends the components working life, keeping industrial weaving operations cost-efficient and consistent.

FAQs of Sulzer Projectile Gripper Feeder:

Q: How do I determine if the Sulzer Projectile Gripper Feeder is compatible with my loom model?

A: This gripper feeder is designed for Sulzer PU, TW11, P7100, and other major Sulzer models. You can confirm compatibility by referencing your looms specifications or by consulting the supplier for model-specific diameter and dimension details.Q: What is the recommended maintenance process for this gripper feeder?

A: Although it requires low maintenance, periodic lubrication is advised to maximize service life and maintain optimal performance during continuous industrial operations.Q: When should the gripper feeder be replaced?

A: The feeder is engineered for service life up to 1 million cycles under recommended conditions. It should be checked periodically and replaced once signs of significant wear or decreased precision in feeding are observed.Q: Where can I source the correct size or dimension for my loom?

A: Model-specific dimensions and diameters are provided upon request. You can obtain accurate sizing information directly from the importer or supplier to ensure a precise fit for your particular Sulzer loom.Q: What are the key benefits of using a Sulzer Projectile Gripper Feeder made from alloy steel?

A: Alloy steel construction provides high tensile strength and superior wear resistance, ensuring extended durability and stability under textile load requirements. This results in consistent performance and reduced replacement frequency.Q: How is the installation process carried out for this component?

A: The gripper feeder is designed for easy, direct mounting onto compatible Sulzer looms. Its ergonomic shape supports quick installation, minimizing downtime and simplifying replacements or upgrades during loom maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email