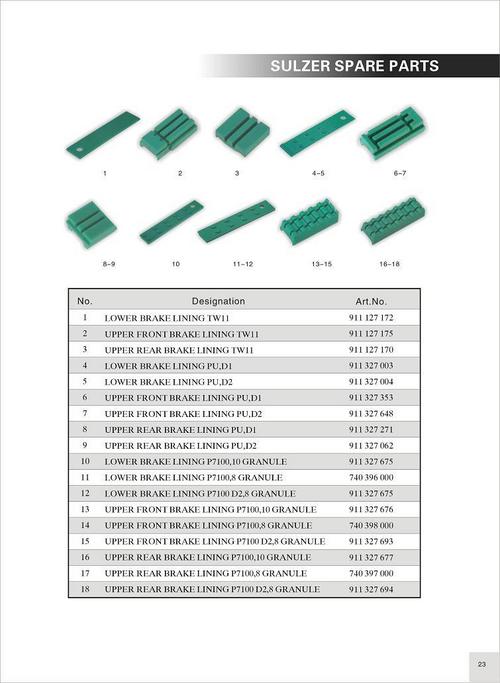

Sulzer Brake Lining

Product Details:

- Diameter Customer Specific

- Surface Finish Coated

- Capacity High Performance

- Part Type Brake Spare Part

- Size Standard / Customizable

- Noise Level Low

- Thermal Conductivity Medium, Heat Resistant

- Click to View more

X

Sulzer Brake Lining Product Specifications

- Sulzer Loom

- Depends on Model

- Durable, Wear Resistant, High Friction Stability

- Standard / Customizable

- Low

- Medium, Heat Resistant

- Manual

- Up to 1000 RPM

- Weaving Machine Brake System

- Coated

- High Performance

- Brake Lining

- Customer Specific

- Brake Lining

- Brake Spare Part

Product Description

We are noted amongst remarkable name enterprises in this domain, engrossed in offering pristine grade Sulzer Brake Lining. The provided product is manufactured under the stern observation of diligent professionals at our highly advanced unit. This product is widely utilized for controlling the movement of weaving and loom machines. In addition to this, the offered Sulzer Brake Lining product provide friction to slow or stop the motion during weaving the clothes.

Features:

- Easy to attach

- Higher strength

- Defect free nature

- Strong design

Enhanced Temperature and Wear Resistance

Our Sulzer Brake Lining offers outstanding heat resistance, capable of withstanding temperatures up to 350C. This attribute ensures consistent braking performance even during prolonged, high-speed weaving operations. Its robust composition guarantees minimal wear and tear, significantly extending service intervals and reducing maintenance costs.

Customizable Design and Compatibility

These brake linings are tailored to fit Sulzer Looms, available in standard or bespoke sizes, shapes, and diameters. The OEM compatibility allows seamless integration with original machine systems. Whether you need a rectangular or a custom profile, our product adapts to a variety of models, ensuring an optimal fit and performance.

Reliable Supplier and Support Across India

As a leading importer and supplier in India, we uphold a strong commitment to product quality and customer satisfaction. Each brake lining is securely packed in boxes for safe transit. Our technical team provides support on installation, usage, and after-sales queries, ensuring you maximize the lifespan and performance of your weaving machine components.

FAQs of Sulzer Brake Lining:

Q: How do I select the correct Sulzer Brake Lining size for my weaving machine?

A: Selecting the right size involves referencing your specific Sulzer Loom model and providing the required dimensions (length, width, height, or diameter). Our team can assist you in identifying the suitable product, whether you need a standard or customized option.Q: What are the benefits of using Sulzer Brake Lining for textile machinery?

A: Benefits include high friction stability, low noise operation, strong heat resistance up to 350C, and remarkable durability. These qualities ensure consistent braking, minimize machine downtime, and extend the maintenance cycle.Q: When should I replace the brake lining in my Sulzer loom?

A: It is recommended to inspect the brake lining regularly, especially if the machine operates at speeds up to 1000 RPM or in high-temperature conditions. Replacement is advised when theres visible wear or when braking efficiency decreases, ensuring safe and effective operation.Q: Where can I purchase Sulzer Brake Lining in India?

A: Sulzer Brake Linings are available through our distribution network across India. We supply directly to customers and offer support to identify the right part for your textile machinery.Q: What is the process for installing the Sulzer Brake Lining?

A: Installation is manual and involves removing the old lining, preparing the mounting surface, and securely fitting the new brake lining as per the manufacturers guidelines. Detailed instructions are provided with each product, and technical support is available if needed.Q: How does the surface finish of the brake lining affect performance?

A: The coated surface finish ensures optimal contact with the braking system, enhancing friction stability and reducing operational noise. This design feature promotes smoother braking and contributes to the linings overall longevity.Q: Can the Sulzer Brake Lining handle high-speed weaving applications?

A: Yes, these brake linings are engineered for high-performance, capable of reliable operation at weaving speeds up to 1000 RPM, ensuring safety and efficiency even under rigorous production conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email