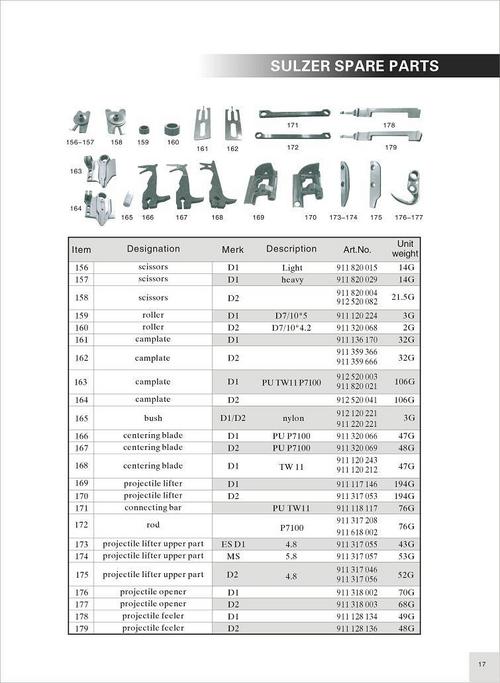

Sulzer Camplate Parts

Product Details:

- Capacity High Performance

- Features Corrosion Resistant, Precision Engineered, Durable

- Noise Level Low

- Diameter Various (as per model)

- Thread Type Metric Fine

- Part Type Textile Machinery Part

- Tensile Strength 1500 MPa

- Click to View more

X

Sulzer Camplate Parts Product Specifications

- Polished

- For Sulzer Looms Cam Mechanism

- Direct Mount

- Manual / Automatic

- As per model specification

- Good

- Standard, custom sizes available

- Various (as per model)

- Metric Fine

- 1500 MPa

- Sulzer Loom

- Alloy Steel

- Textile Machinery Part

- High Performance

- Spare Part

- Corrosion Resistant, Precision Engineered, Durable

- Camplate Parts

- Up to 900 RPM

- Low

Product Description

For past 12 years, we have been instrumental in putting forth top grade Sulzer Cam Plate Parts. With the aid of contemporary techniques, these parts are manufactured using supreme quality basic materials. Having capability of performing weaving process in efficient manner, the offered parts are perfect for all types of clothes in textile industry. In addition, these Sulzer Cam Plate Parts are highly cherished among clients due to their rust as well as bent proof nature.

Features:

- Superior efficiency

- Long life

- Simple installation

- Easy of handling

Precision Engineering for Reliable Performance

Our Sulzer Camplate Parts are CNC machined with high-grade alloy steel, ensuring excellent tensile strength (up to 1500 MPa) and durability. Crafted to maintain tight tolerances, these camplates offer high precision, resulting in smoother motion, lower noise, and reduced wear during loom operation. The polished surface finish further enhances efficiency by minimizing friction and corrosion risk.

Versatile Compatibility and Custom Sizes

Designed to fit standard Sulzer loom models, our camplates are also available in custom sizes and diameters to suit varied customer requirements. With direct mount installation and metric fine threading, compatibility and installation are straightforward, reducing downtime during part replacement. Detailed sizing ensures a proper fit for efficient operation and broad coverage across machine types.

Ready Stock and Efficient Supply

We maintain ready stock for common Sulzer camplate parts, enabling same-day dispatch within India or a 7-day lead time for special orders. Every part is box packed for safe transit, and our ISO-certified processes ensure consistent quality. OEM services are available to tailor parts according to unique textile manufacturing needs, providing both standard and specialized solutions.

FAQs of Sulzer Camplate Parts:

Q: How do Sulzer Camplate Parts ensure high precision and durability in textile looms?

A: Sulzer Camplate Parts are CNC machined from polished alloy steel, offering a tensile strength of 1500 MPa. This manufacturing process ensures each part meets tight tolerances for consistent cam operation, minimizing wear and extending service life, even in high-speed textile environments.Q: What standard and custom sizes are available for these camplates?

A: We supply camplates in standard sizes suitable for most Sulzer loom models. Custom dimensions and diameters can be manufactured upon request, ensuring compatibility with specific machine requirements or unique operational setups.Q: When should I consider replacing the Sulzer Camplate Parts in my loom?

A: These camplates have a long service life due to their robust material and finish. Replacement is generally recommended during scheduled maintenance or when signs of excessive wear, noise, or decreased loom performance become evident.Q: Where can these Sulzer Camplate Parts be used?

A: These parts are specifically designed for the cam mechanism in Sulzer looms used in the textile industry. Their versatility allows them to be installed in both manual and automatic loom systems, accommodating a wide range of production setups.Q: What is the recommended maintenance process for these camplates?

A: Periodic greasing is necessary to maintain optimal performance and prevent premature wear. Routine inspection during maintenance cycles will help ensure lubrication is sufficient and the components remain in top condition.Q: How do these camplates benefit the textile manufacturing process?

A: By providing a reliable, corrosion-resistant component that operates at up to 900 RPM with low noise, these camplates maximize loom uptime and fabric quality while minimizing maintenance interruptions and operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email