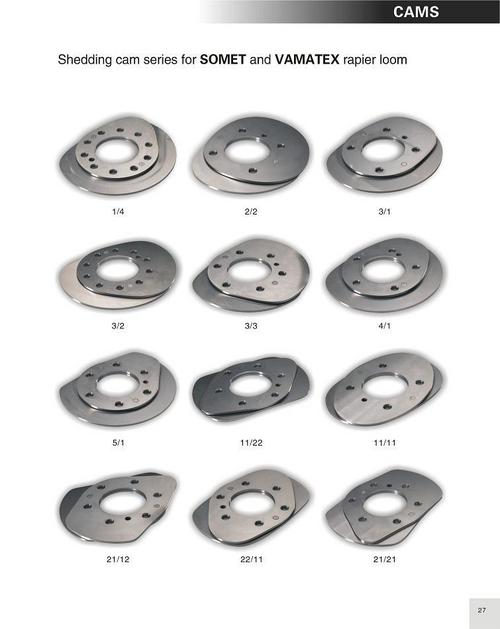

Shedding Cam

Product Details:

- Mounting Type Bored/Keyed Mount

- Part Type Cam

- Features Corrosion Resistant, Wear Resistant, Durable

- Surface Finish Polished

- Size Standard

- Tensile Strength High Tensile

- Thermal Conductivity Good

- Click to View more

X

Shedding Cam Product Specifications

- Up to 1000 RPM

- Alloy Steel

- Shedding Cam

- Shedding Mechanism Component

- Standard

- High Tensile

- Low

- 3

- 1.2 kg

- Good

- As per drawing

- Bored/Keyed Mount

- High

- Cam

- Manual

- Loom/Weaving Machine

- Corrosion Resistant, Wear Resistant, Durable

- Customized

- Industrial Textile Machinery

- Polished

Product Description

We have been noted amidst the trustworthy entities, engrossed in putting forth top grade Shedding Cam. The offered camera is manufactured under the strict vigilance of dedicated professionals by utilizing fine quality basic materials at our highly advanced unit. This cam is ideal to control the n movement of head shaft during weaving process. The provided Shedding Cam can be bought by our valued patrons at affordable prices.

Features:

- Require less maintenance

- Provides great output

- Sturdiness and strong design

- Compact sizes

Premium Machining for Peak Performance

Each Shedding Cam is crafted through precision machining, ensuring dimensional accuracy and a polished surface finish. This technological approach guarantees optimal performance in high-speed industrial textile environments, enhancing wear resistance and improving the shedding mechanisms reliability during loom operation.

Universal Compatibility and Robust Design

With its standardized size and chamfered/smooth edges, the Shedding Cam is universally compatible with most textile weaving machines. The bored/keyed mounting system enables easy installation and secure attachment, while the alloy steel material provides high tensile strength for demanding operational speeds up to 1000 RPM.

Corrosion & Abrasion Resistance for Extended Service

Engineered to withstand corrosive and abrasive industrial conditions, the Shedding Cams durable alloy steel and polished finish protect against environmental damage. Its excellent thermal conductivity and high tensile capacity underscore its suitability for extended use in textile machinery.

FAQs of Shedding Cam:

Q: How does the Shedding Cam improve textile loom operation?

A: The Shedding Cam enhances loom performance by delivering precise shed formation, low noise levels, and improved wear resistance. Its high tensile alloy steel construction supports efficient weaving, withstanding the mechanical stress of speeds up to 1000 RPM.Q: What steps are involved in manufacturing the Shedding Cam?

A: Shedding Cams undergo precision machining from alloy steel followed by polishing for a smooth finish. Edges are chamfered for safety and compatibility, and each unit is bored and keyed for secure mounting. Quality control ensures corrosion and abrasion resistance before boxing for shipment.Q: When should I consider replacing the Shedding Cam in my weaving machine?

A: Its recommended to replace the Shedding Cam when signs of excessive wear, reduced shed formation efficiency, or increased noise during operation become evident. Regular inspection helps maintain optimal machine performance and extend working life.Q: Where can I source Shedding Cams for my textile looms?

A: Shedding Cams are available through reliable importers and suppliers throughout India. Ensure your supplier provides genuine, boxed components with the specified features for guaranteed compatibility and durability.Q: What are the main benefits of using this Shedding Cam in textile machinery?

A: Users gain extended working life, high capacity, and reliable performancethanks to its durability, corrosion and abrasion resistance, and universal fit. The component maximizes efficiency and reduces maintenance for industrial weaving applications.Q: How do I install the Shedding Cam onto my loom?

A: The Shedding Cam is designed for bored/keyed mounting. Carefully align the cam with the bore and key slots, insert securely, and tighten any necessary fixtures. Refer to machine specifications for diameter and dimensions as per the provided drawing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email